首页>>product>>vibrating screen / heavy duty linear vibrating screen

Unit integration, diverse configuration

Model number:Customize according to demand

yield:15-500 t/h (output varies according to material characteristics)

Use:Mining, coal, electricity, metallurgy, building materials, refractories.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

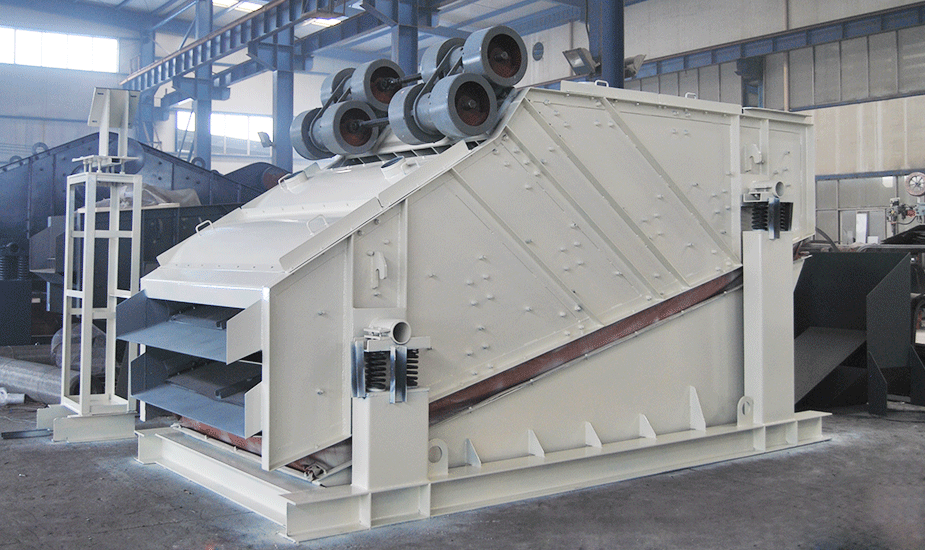

Heavy-duty linear vibrating screen is a new general-purpose screening equipment, the motion path of the screen box is approximately straight. The linear vibrating screen has simple structure, large screening capacity, low energy consumption and easy maintenance, and is widely used in mining, coal, electric power, metallurgy, building materials, fire resistance and other industries for the classification of large block materials and medium and small granular materials.

The basic working principle of ZSG type heavy vibrating screen is that after the screen machine is started, two vibration motors or exciters of the same model and specifications are symmetrically arranged for synchronous reverse operation, and the exciting force generated by them is transmitted to the whole vibrating body - screen box through the vibration transfer body - motor or the base of the exciter, so that the screen box drives the screen surface for periodic vibration. So that the material on the screen surface with the screen box to make a directional jump movement, during which, less than the screen surface aperture of the material through the screen to fall to the lower layer, become under the screen, greater than the screen surface aperture of the material after continuous jumping movement from the discharge port, to complete the screening operation.

There is no fixed model. Customize according to requirements

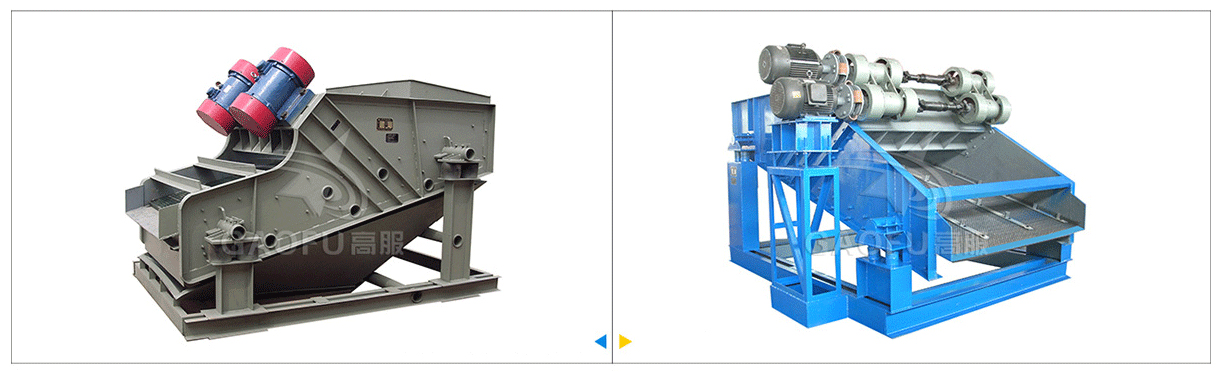

● The power unit has two forms of direct drive by vibration motor and indirect drive by ordinary motor driven by vibration exciter through coupling, which can meet the needs of different production environments.

● The screen surface has a variety of forms such as metal braid net, bar, punching, etc. The screen surface can be arranged in either single layer structure or multiple layers to meet the requirements of different screening operations.

● The structure is simple and easy to operate, beautiful appearance, the stiffness of the whole machine and the strength of each part, relatively less energy consumption, high screening efficiency.

● Relatively small size, light weight, large unit equipment volume and weight processing capacity, easy to system process layout.

● Screen surface structure and type modular design, easy to replace, can meet the needs of different environmental operations.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!