Unit integration, diverse configuration

Model number:GFD-1P1S to 24P2S

yield:15-500 t/h (output varies according to material characteristics)

Use:Suitable for refining, pharmaceutical, chemical, biological, vegetable oil, industrial oil and other easy crystallization, low temperature solidification of solid and liquid separation industry

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

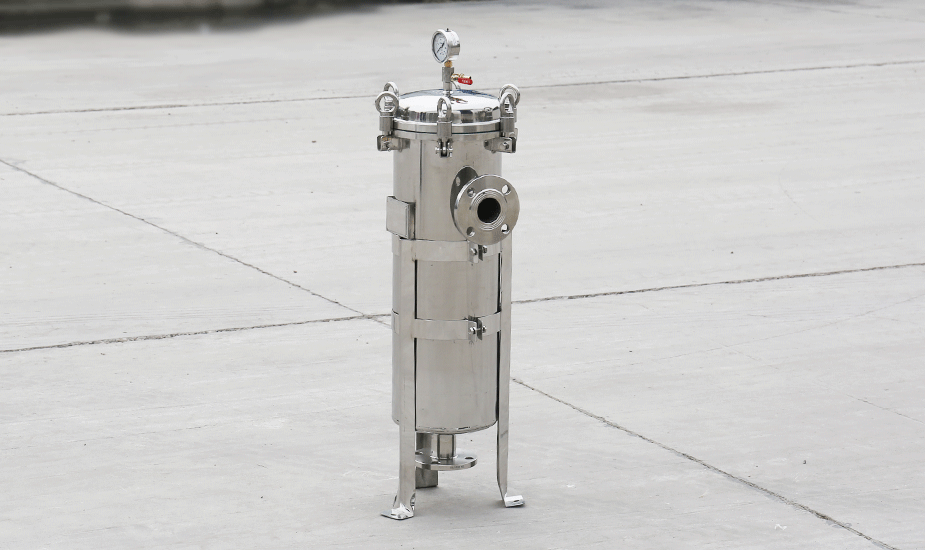

Bag filter is a kind of multi-purpose filter equipment with novel structure, small size, simple and flexible operation, energy saving, closed work and strong adaptability. Bag filter is mainly composed of filter cylinder, filter cylinder head and quick-opening mechanism, stainless steel bag strengthening net and other main components.

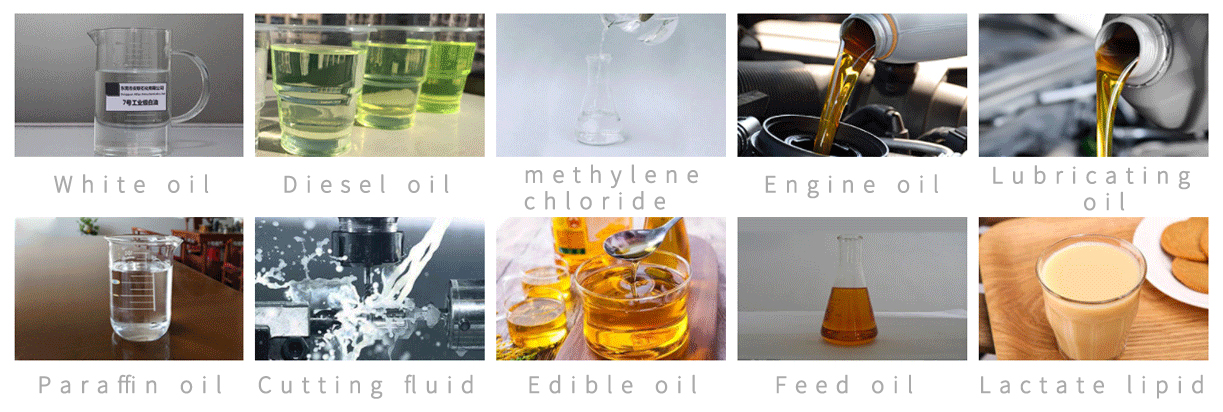

Paint, beer, vegetable oil, medicine, cosmetics, chemicals, petroleum products, textile chemicals, photosensitive chemicals, electroplating solution, milk, mineral water, hot solvent, latex, industrial water, sugar water, resin, ink, industrial wastewater, fruit juice, edible oil, etc.

The multi-bag filter is mainly composed of filter cylinder simplified, filter cylinder head and quick-opening mechanism, stainless steel bag strengthening net and other main components. This series filter is a pressure type filter device. The raw liquid flows into the filter bag in the reinforced mesh through the feed port, and is pressurized. The qualified product penetrates into the filter bag and is discharged through the discharge port and enters the next process. The impurity particles are captured by the filter bag. The whole process is efficient, simple, and basically does not produce material consumption.

| Model number | Filter area (㎡) | Inlet diameter (mm) | High flow (m³/h) | High working pressure (MPa) | High operating temperature (℃) | Nominal filtration accuracy (μm) |

| GFD-1P1S | 0.25 | φ40 | 18 | 0.5 | 150 The operating temperature is related to the use of filter bag (stainless steel filter) material | 1、5、10、15、25、40、50、60、75、80、100-1200 |

| GFD-1P2S | 0.5 | φ40 | 36 | |||

| GFD-4P1S | 1 | φ80 | 70 | |||

| GFD-4P2S | 2 | φ100 | 140 | |||

| GFD-6P2S | 3 | φ150 | 210 | |||

| GFD-8P2S | 5 | φ250 | 280 | |||

| GFD-10P2S | 6 | φ250 | 350 | |||

| GFD-12P2S | 7 | φ300 | 420 | |||

| GFD-16P2S | 10 | φ300 | 560 | |||

| GFD-20P2S | 12 | φ350 | 700 | |||

| GFD-24P2S | 14 | φ350 | 840 |

● Suitable for fine particles or suspended matter, large treatment flow per unit filtration area, small filtration resistance, high filtration efficiency. The filtration function of a liquid filter bag is equivalent to 5-10 times the filter element, which can reduce the cost; The design flow can meet the requirements of 1-500m3 /h, and the cost is low.

● Widely used, can be used for coarse filter, medium filter or fine filter; In the case of achieving the same filtering effect, compared with plate and frame fine filter, filter core filter and other equipment has the advantages of low investment cost, long service life and low filtration cost.

● Liquid bag filter specifications are complete, can meet different flow filtration requirements, low pressure type, side entry type, top entry type, multi-bag type, horizontal, material including stainless steel SUS304, 316, 316L.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!