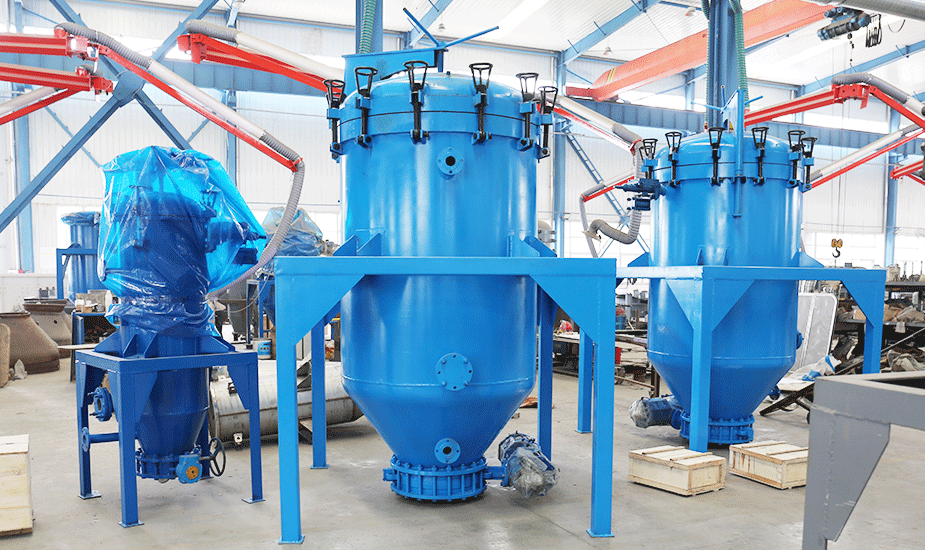

Unit integration, diverse configuration

Model number:GLJ-4 to 80 (special models need to be customized)

yield:15-500 t/h (output varies according to material characteristics)

Use:Activated carbon decolorization filtration

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

Closed environmental protection leaf filter is our company according to the industry solid-liquid separation and filtration common problems, the introduction of industry international technology development and development, filter leaf adopts special stainless steel filter, long life, large output, high precision; Self-created oil pressing mechanism, low oil content in the slag, easy to operate, easy to discharge, suitable for oil, chemical, pharmaceutical and other industries in the production of decolorized oil filtration, clarification filtration, crystal filtration separation process, especially to solve the oil industry in cottonseed, rapeseed, castor and other machine-pressed crude oil is difficult to filter, not easy to discharge the slag and other problems.

Petrochemical: polyether, diesel oil, lubricating oil, white oil, transformer oil Mineral oil and base oil: dibutyl ester, dioctyl ester

Oils and fats: crude oil, bleached soil, hydrogenated oil, winterized oil, stearin, fatty acids, etc

Food: gelatin, salad oil, starch, sugar juice, MSG, milk, vinegar, etc

Pharmaceutical: hydrogen peroxide, vitamin c, glycerin, etc

Coatings: varnish, resin paint, dye, 685 varnish, etc

Organic chemical industry: various organic acids, alcohols, esters, benzene, aldehydes and so on

Inorganic chemical industry: bromine water, potassium cyanide, fluorspar, etc

Automatic slagging filter by the gear oil pump (centrifugal pump) the mixing tank mixed clay mixture liquid pumped through the pipeline into the filter tank and filled with, under the thrust of the pump, through the circulation of large particles of clay on the surface of the filter screen to form a filter cake layer, under the action of the filter cake layer, fine particles of clay are trapped to form countless fine channels. Then the more subtle suspended matter is intercepted, only clear liquid is allowed to pass, then filtration begins, in the filtration process through the continuous new clay mixture pumped into the formation of a new filter cake layer, so that the filter cake will not be blocked, so that the material through the filter cake layer for substantial filtration, clear liquid through the filter screen internal channel through the oil nozzle flow to the outlet pipe, Under the thrust of the pump, it flows through the pipeline to the finished product tank.

With the increase of the filtration amount of the clay mixture, the cake layer becomes thicker and thicker, the filtration resistance increases, and the pressure in the tank rises. When the pressure gauge at the part of the filter machine shows 0.4Mpa, stop conveying the clay mixture into the filter tank, start the air compressor, and input air into the filter tank through the overflow port through the pipeline. Under the action of air pressure, the oil in the cake is gradually pressed out. After about 30 minutes, the filter cake is pressed dry, stop the input of air into the filter, when the pressure gauge of the filter part shows 0, open the butterfly valve, start the vibration body, and start the slag discharge, when the slag discharge is clean, close the butterfly valve and all valves, and start the next round of filtration.

| Model number | Filter area | Barrel diameter | entrance | exit | Overflow port |

| GLJ-4 | 4㎡ | 550 | DN50 | DN80 | DN40 |

| GLJ-8 | 8㎡ | 700 | DN50 | DN80 | DN40 |

| GLJ-10 | 10㎡ | 800 | DN50 | DN80 | DN40 |

| GLJ-15 | 15㎡ | 900 | DN50 | DN80 | DN40 |

| GLJ-20 | 20㎡ | 1100 | DN50 | DN80 | DN40 |

| GLJ-30 | 30㎡ | 1200 | DN50 | DN80 | DN40 |

| GLJ-40 | 40㎡ | 1300 | DN65 | DN80 | DN50 |

| GLJ-50 | 50㎡ | 1400 | DN65 | DN80 | DN50 |

| GLJ-60 | 60㎡ | 1500 | DN65 | DN80 | DN50 |

| GLJ-80 | 80㎡ | 1600 | DN65 | DN80 | DN50 |

● Mechanical vibration automatic slagging, open the butterfly valve, start the vibration slagging device, vibration slagging, reduce the labor intensity of workers, to achieve continuous operation.

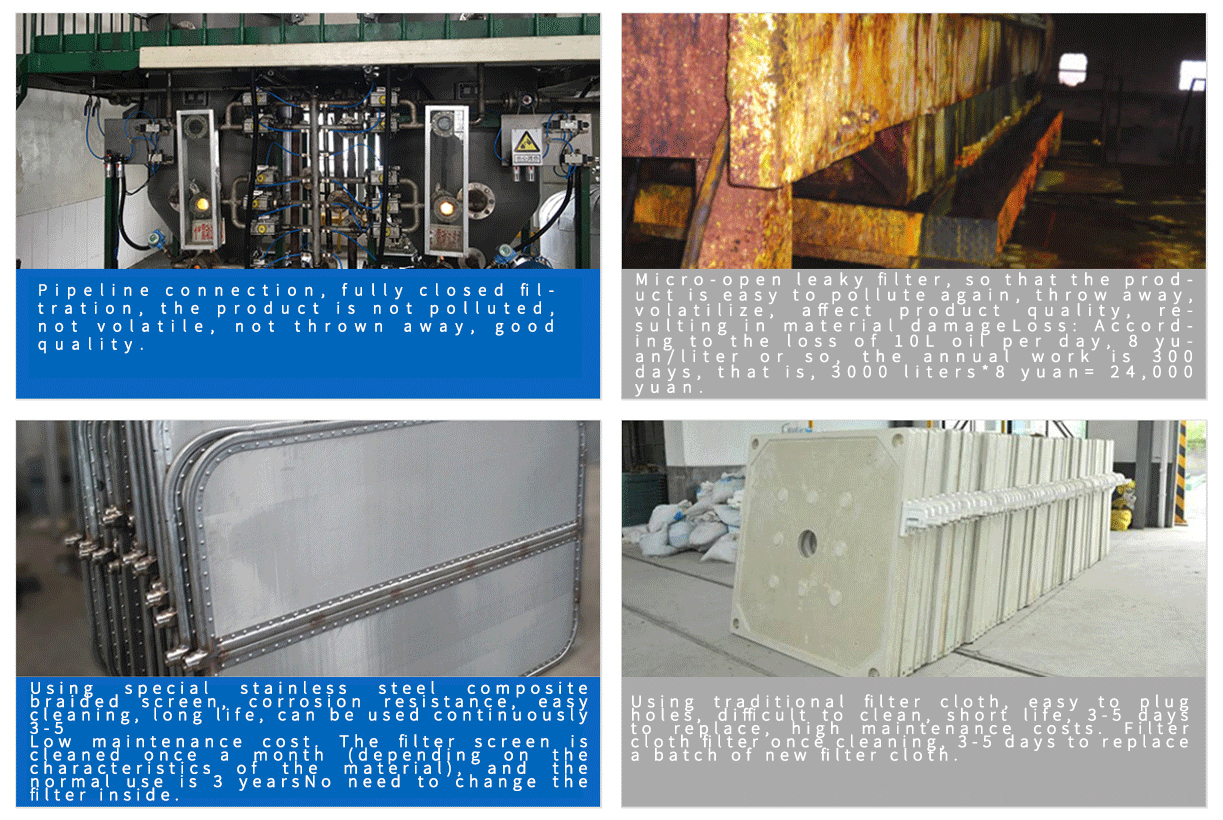

● Special filter plate, no filter cloth, filter paper, automatic slag filter adopts special stainless steel composite braid filter, corrosion resistance, easy cleaning, long life, can be used for 3-5 years, low maintenance cost.

● Closed environmental protection, in line with environmental standards, pipeline connection, fully closed filtration, products do not volatilization, do not throw, good quality.

● High energy saving efficiency, filter liquid slag or activated carbon (white soil), or decolorization filter, can replace the plate and frame filter.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!