首页>>product>>Vibrating conveyor / Vibrating hopper

Unit integration, diverse configuration

Model number:Customize according to demand

yield:15-500 t/h (output varies according to material characteristics)

Use:Metallurgy, mining, chemical, food, medicine, chemical and other industries

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

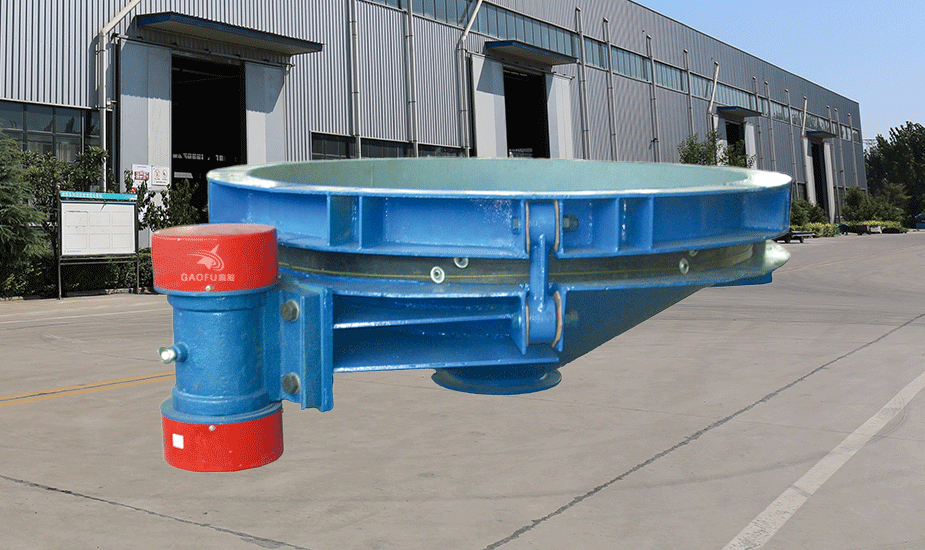

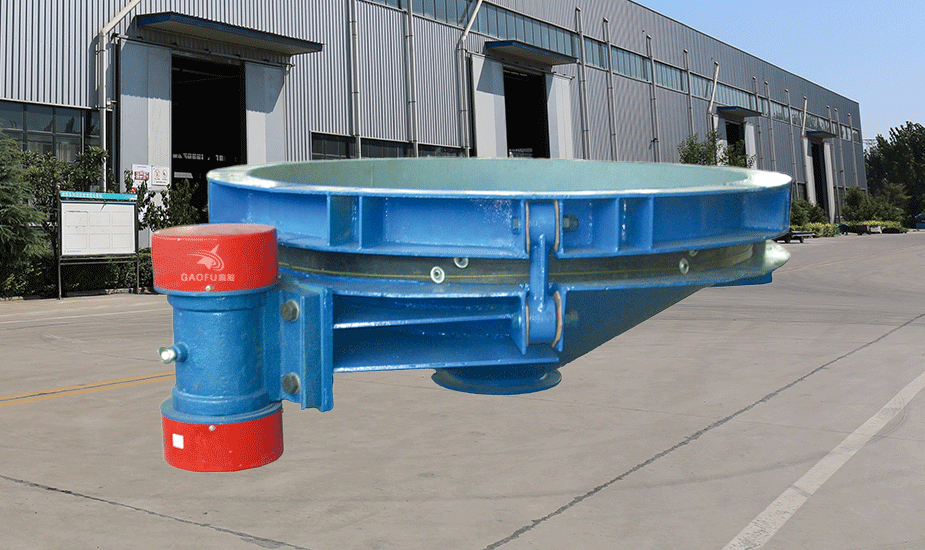

The vibrating hopper is a kind of feeding equipment which is rigidly connected with the bin. The vibration feed hopper has good arch breaking performance, which can achieve arch breaking and continuous uniform discharge for various powder and granular materials in the bin, and can eliminate the segregation phenomenon of mixed materials with different particle size and different specific gravity when entering the bin. Its simple structure, reliable work, smooth operation, low noise, less power consumption, long service life, maintenance workload is small, productivity adjustment range is large. Suitable for any round, square, steel or concrete silo. Can achieve completely sealed transmission, dust is not exposed, does not pollute the environment. The selection of a vibration hopper that meets the actual requirements is the premise of ensuring the normal operation of the vibration hopper. For the selection of a vibration hopper, it is necessary to determine the characteristics of the material, the geometric size and structure of the bin, and the requirements of the adjustment characteristics of the vibration hopper in production operation. The redesigned vibration hopper also needs to determine or calculate reasonable structural parameters, motion parameters, dynamic parameters and electrical parameters.

Zinc powder, graphite powder, tree fat powder, Chinese medicine powder, fire extinguishing agent, plastic powder, clay, abrasive material, aluminum powder, glass powder, refractory material, starch, milk powder, metallurgical powder, electromagnetic material, copper powder, carbon black, activated carbon, heavy calcium carbonate, iron ore, magnetic material, zinc borate, magnesium oxide, light magnesium oxide, barium sulfate, zinc oxide, manganese dioxide and other powder materials

The vibrating hopper uses the vibrating directional mechanism to automatically feed material to the hopper. The vibrating hopper is composed of the hopper, the supporting spring, the directional mechanism, the electromagnet and the base and other components. The hopper is mostly disc type, of course, there are straight groove type. Vibration hopper is a continuous feeding device. By changing the input voltage of the electromagnet coil, the vibration hopper can adjust the vibration amplitude of the tray, and then adjust the feed rate of the hopper.

No fixed model, customized according to demand.

1, broken arch, feed, gate three as one.

2, feed continuous, uniform, can be timed quantitative, stepless adjustment.

3, simple structure, easy installation, reliable operation.

4, good sealing, no need for local dust removal or anti-gas.

5, light weight, low power consumption, low noise.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!