首页>>product>>Vibrating conveyor / Vibrating conveyor

Unit integration, diverse configuration

Model number:Customize according to demand

yield:15-500 t/h (output varies according to material characteristics)

Use:Metallurgy, coal, building materials, chemical, food and other industries

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

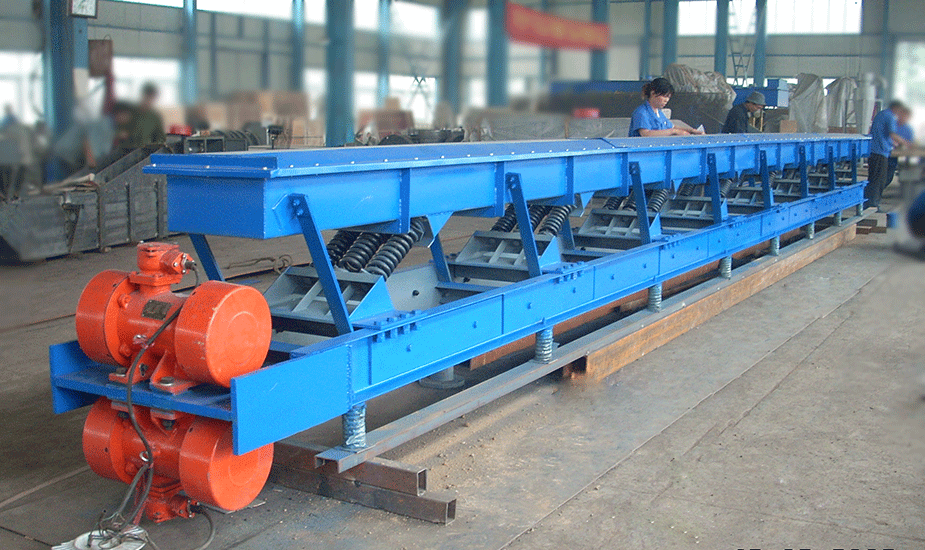

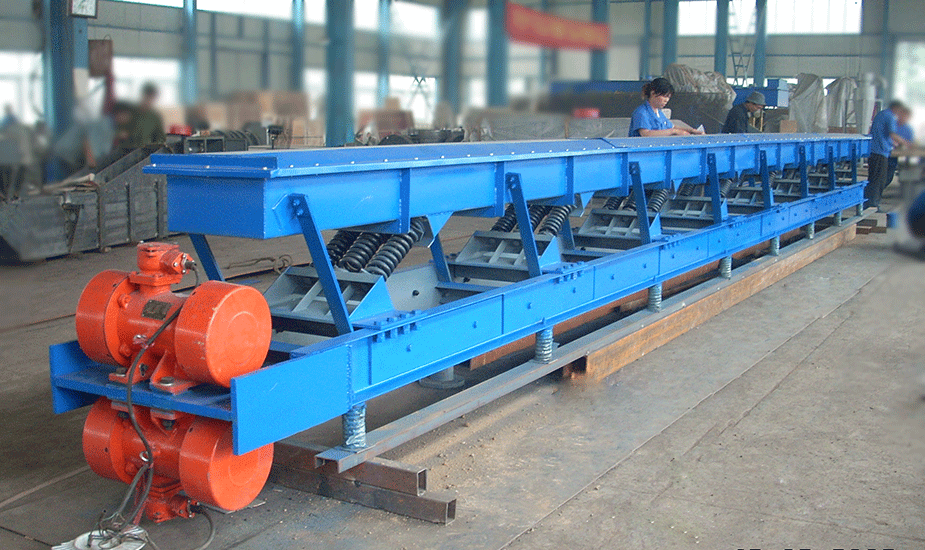

Vibration conveyor is a continuous conveying machine that uses vibration exciter to make the trough vibrate, so that the material in the trough slides or is thrown in a certain direction. Generally used for horizontal transportation, the productivity is less than 150t/ h, the transportation distance is less than 80m, and the productivity decreases with the increase of the inclination Angle. In addition to some parts of the exciting mechanism, the relative rotating parts are few, the structure is simple, can transport various particle size materials, can be hot, flammable and explosive, toxic, dusty materials closed transport, in the transport process can be completed at the same time screening, dehydration and cooling process operations. However, it is not suitable to transport viscous materials. Commonly used in chemical and building materials factories.

Powder, granular materials, etc

Vibration conveyor is generally composed of vibration source - vibration motor or exciter, carrier, vibration reduction support, bearing foundation and related accessories. According to the site use environment and the characteristics of conveying materials, the conveyor carrier can be processed into U-shaped groove and tubular and other structural forms using different materials, and can be made into open or closed types according to the sealing requirements to meet different technological processes; Because the carrier of the equipment is metal parts and the lubrication point is far away from the material, the machine can not only transport a variety of normal temperature, ordinary materials, but also can transport a lot of high temperature, toxic and other unconventional materials; If the carrier is specially processed, the process requirements of material screening, drying, heating and cooling can be realized in the conveying process.

No fixed model, customized according to demand.

The machine has the advantages of simple structure, easy installation and maintenance, low energy consumption, no dust overflow, low noise, strong conveying capacity and so on, which are widely used in various industries.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!