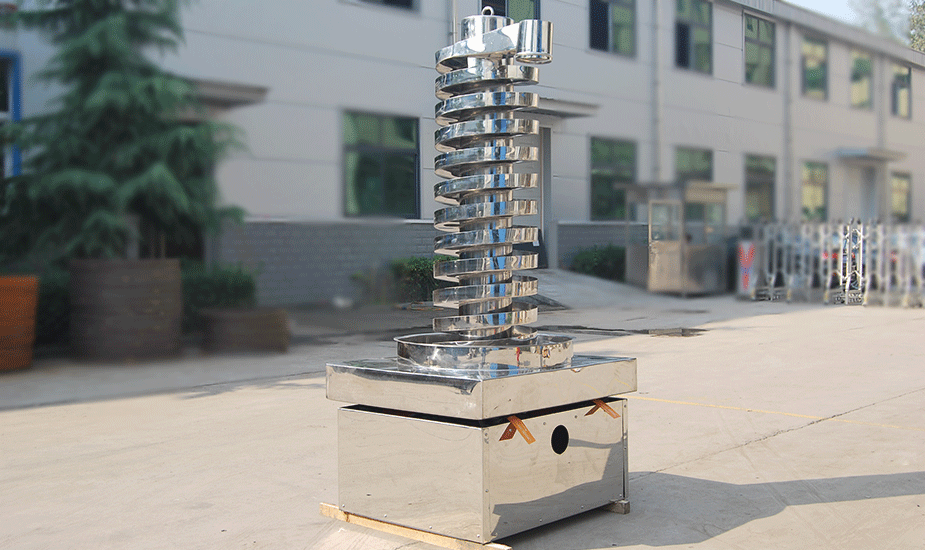

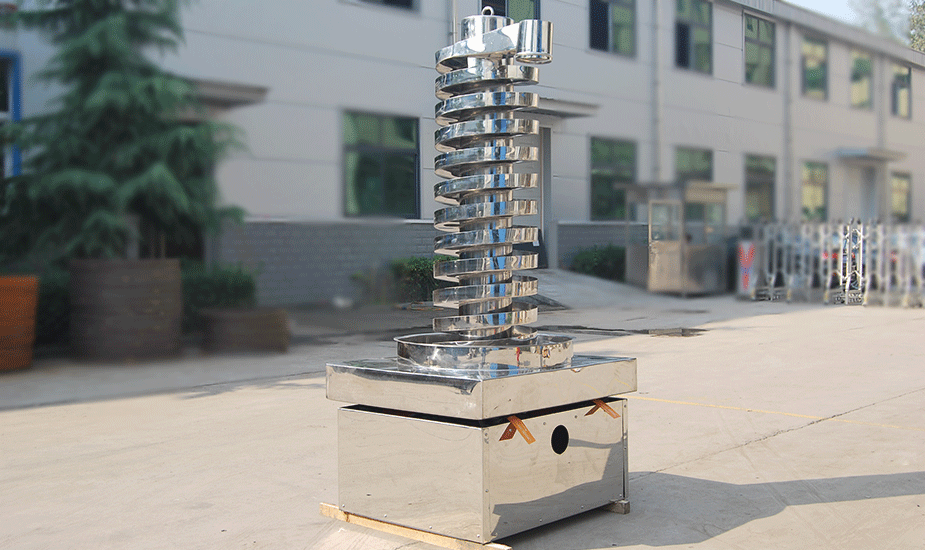

首页>>product>>Vibrating conveyor / Vertical elevator

Unit integration, diverse configuration

Model number:On-demand customization

yield:15-500 t/h (output varies according to material characteristics)

Use:Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metallic industry, other industries, etc

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

The vertical elevator uses vibration motor as vibration source, and uses the synthetic amplitude of the two vibration motors to transport the material upward along the spiral conveyor groove. DZC vertical conveyor is mainly used to lift granular, powdery, block materials. The conveyor has the advantages of simple structure, easy maintenance, quantitative material delivery, continuous adjustable conveying capacity, and can be used as the vertical conveying of small particle materials in various industries. In addition to lifting the material from the bottom up, it can also complete the drying and cooling of the material. Separate trough type, closed two structures, and according to the requirements of different processes, the design of material particle grading screening hoist and the design of flammable and explosive material hoist.

Carbon black (white carbon black), quartz powder (sand), mica, phosphor, feldspar powder, kaolin, siliceous black soil, fly ash, glass microbeads, environmental protection, plastics, plastics, magnetic materials, building materials, mining, kiln industry, feed, condiments, fish meal, rice flour, flour, soybean powder, milk powder, egg powder, starch, sugar, juice, Western medicine powder, Chinese medicine powder, pharmaceutical intermediates, pearl powder, soda ash, poly Ethylene, resin powder (PVC, epoxy), laundry powder, additives, paint, dyes, pigments, rubber, coatings, alloy powder, gold powder, silver powder, copper powder, aluminum powder, nickel powder, chromium powder, magnesium powder, zinc powder, barium powder, vanadium powder, titanium powder, strontium powder, lead powder, casting sand, etc.

The vertical elevator is composed of lifting groove, vibration motor, vibration damping system and base. This series of hoist is the vibration motor as the vibration source, fixed on the lifting groove of two of the same type of vibration motor center line cross a certain Angle installation, and do the opposite direction of self-synchronous rotation, vibration motor with the eccentric block in the rotation of each instant position of the centrifugal force generated by the force reciprocating along the throwing direction. The whole body supported on the shock absorber keeps vibrating, so that the material is thrown up in the lifting groove at the same time upward movement, the material falls into the feeding groove, began to be thrown up, at this time can make the material fully contact with the air, but also can play a cooling role. The elevator can vertically transport solid materials (except those that are sticky and easy to caking) in the form of powder, block and short fiber, and can also complete the drying and cooling of materials. Divided into open, closed two kinds of structure. It can be specially designed according to the needs of users.

No fixed model, customized according to demand.

● Small size, light weight, good sealing performance, low dust, high efficiency.

● Small footprint, energy saving, environmental protection.

● Large conveying output, strong adaptability for chip loading and granular materials.

● Simple operation, easy maintenance.

● Meet the requirements of GMP standards, easy to clean; Do not cause secondary pollution of materials.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!