首页>>product>>Vibrating conveyor / Vacuum feeder

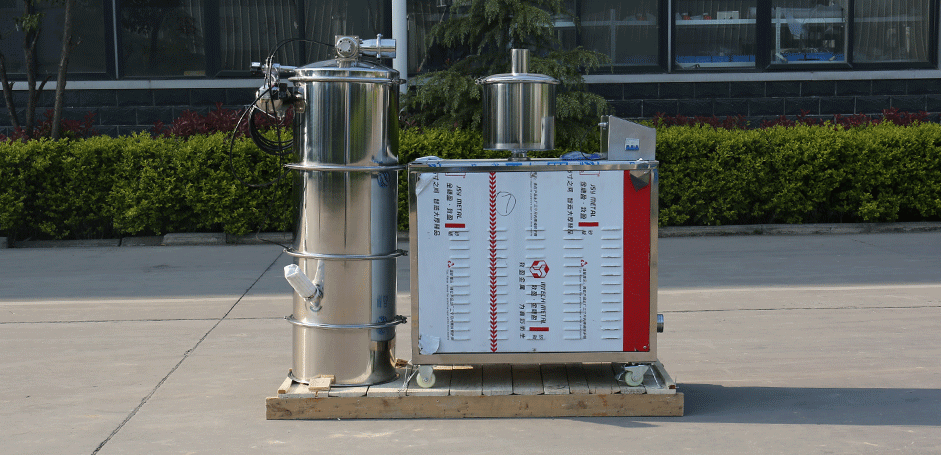

Unit integration, diverse configuration

Model number:ZKS-1 through 20

yield:15-200 t/h

Use:Used for conveying powder and granular materials in food, pharmaceutical, chemical and other industries.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

ZKS vacuum charging machine is pumped by vacuum pump, so that the inlet of the suction nozzle and the whole system is in a certain vacuum state, powder particles with the outside air is sucked into the nozzle, forming a material flow, through the suction tube to the hopper, in the hopper for gas and material separation. The separated material enters the receiving equipment. Conveying and discharging materials are completed by constantly opening and closing the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is controlled by the control panel. ZKS vacuum feeding machine is equipped with compressed air blowback device, each time the material is discharged, compressed air pulse blowback filter, the powder adsorbed on the surface of the filter to knock down, so that the suction can run normally.

Various powder materials

The negative pressure generated by the vacuum feeder inhales the material from the feed port, and then filters it in the separated container, separating the air and the material. The material will automatically fall because of its own gravity, and the material will be collected in the bin. The cyclone separator enters the filter through the fine powder to improve the efficiency of the filter. When the silo is filled with material, the vacuum pump will automatically close, and the pressure of the conveying equipment will reach balance.

The compressed air automatically cleans the filter through the pulse reverse valve, and when the time is up, the material level sensor will send out a feeding signal, which is the vacuum feeder will start the feeding function, which has the advantages of simple structure and convenient control.

| Model number | Motor power (kW) | Conveying capacity (kg/h) |

| ZKS-1 | 1.5 | 400 |

| ZKS-2 | 2.2 | 600 |

| ZKS-3 | 3 | 1200 |

| ZKS-4 | 5.5 | 2500 |

| ZKS-6 | 5.5 | 3200 |

| ZKS-7 | 7.5 | 6000 |

| ZKS-10-6 | 7.5 | 6000(When the conveying distance is 10 meters) |

| ZKS-20-5 | 11 | 5000(Conveying distance of 20 meters) |

Note: The conveying capacity is measured when the conveying pipe is 4 meters long and the conveying material is flour. The longer the conveying pipe, the conveying capacity will decrease, and the conveying capacity also has a great relationship with the characteristics of the material.

● Reduce environmental and personnel pollution of materials, improve cleanliness.

● Small occupation space, can complete the powder conveying in a small space, so that the working space is beautiful and generous, and is not limited by the length and distance.

● The whole conveying process is carried out in a closed system, without powder leakage.

● Easy visual inspection, the equipment has no gap or dead Angle that is easy to make material accumulation, and the surface is easy to visual inspection.

● Reduce manual labor intensity and improve work efficiency.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!