首页>>product>>Industrial Vibrating Screen / Ultrasonic vibrating screen

Unit integration, diverse configuration

Model number:S49-AC-600 to 2000

yield:15-500 t/h (output varies according to material characteristics)

Use:Battery materials, silicon powder, food industry, pharmaceutical industry, chemical industry, metal, metallurgy and mining, non-metal industry, other industries, etc.

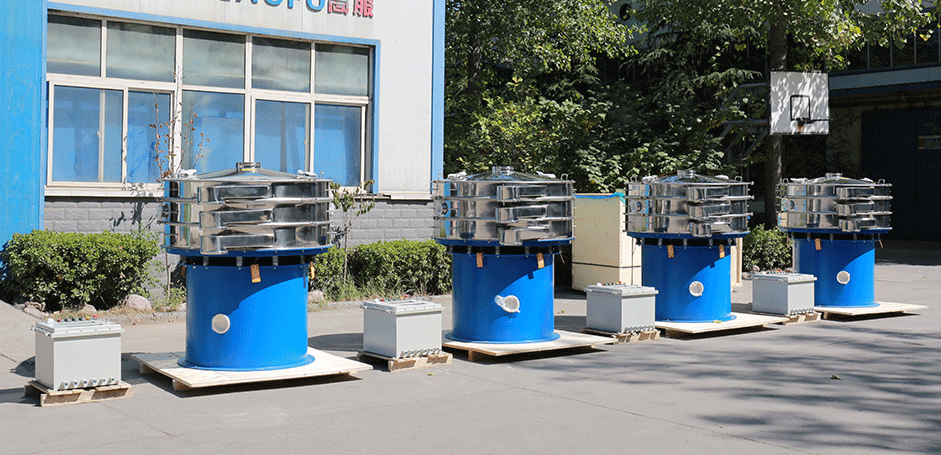

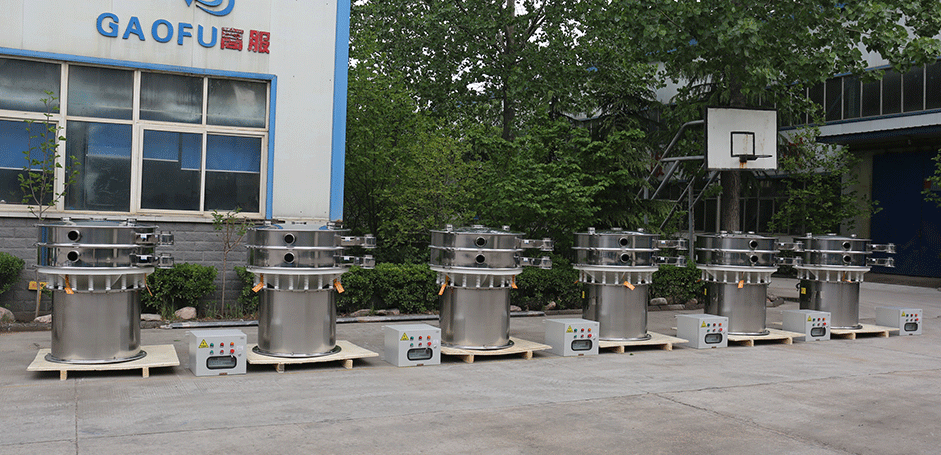

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

Ultrasonic vibrating screen, also known as ultrasonic vibrating screen and ultrasonic rotary vibrating screen, adds ultrasonic function on the basis of ordinary rotary vibrating screen to improve the screening accuracy and passing rate of materials, and solves the screening problems such as strong adsorption, easy agglomeration, high static electricity, high fineness, high density and light specific gravity, so that fine powder screening is no longer a difficult task. Gaofu ultrasonic vibrating screen has been well received and praised by users at home and abroad!

The 220V, 50Hz or 110V, 60Hz electric energy is converted into 18KHz high-frequency electric energy, which is input into the ultrasonic transducer to convert it into 18KHz mechanical vibration. The generated power ultrasonic wave makes the screen vibrate at high frequency. While the material on the screen is performing low-frequency rotation and vibration, the ultrasonic vibration is superimposed, which can not only prevent the mesh from being blocked, but also improve the output and quality of the screening machine, thereby achieving the purpose of screening and cleaning the screen, making the screening of ultrafine powders easy. Based on the traditional vibrating screen, this system introduces a low-amplitude, high-frequency ultrasonic vibration wave (mechanical wave) on the screen to improve the screening performance of ultrafine particles. It is particularly suitable for users with high added value fine separation.

| model | Effective screening diameter (mm) | Effective screening area (㎡) | Screen specifications(Mesh/inch) | Number of layers (s) | Vibration Motor (kW) | Ordinary motor (kW) |

| S49-AC-600 | Φ560 | 0.23 | 2-500 | 1-5 | 0.25 | 0.75 |

| S49-AC-800 | Φ760 | 0.42 | 1-5 | 0.55 | 1.1 | |

| S49-AC-1000 | Φ930 | 0.64 | 1-5 | 1.1 | 1.5 | |

| S49-AC-1200 | Φ1130 | 0.95 | 1-5 | 1.1 | 1.5 | |

| S49-AC-1500 | Φ1430 | 1.61 | 1-4 | 1.5 | 2.2 | |

| S49-AC-1800 | Φ1730 | 2.35 | 1-3 | 3 | 3 | |

| S49-AC-2000 | Φ1920 | 2.9 | 1-3 | 3 | 3 |

● Gaofu combines ultrasonic and vibrating screens to solve the problem of difficult screening of highly adsorbent materials.

● It solves the screening problems of materials with strong adsorption, easy to agglomerate, strong viscosity, high static electricity, high density, ultrafine powder and other characteristics.

● The screening accuracy can be increased by more than 80, and the output can be increased by 2 to 5 times.

● It changes the pollution and wear of powder caused by conventional screening methods, and greatly reduces the noise of the screening machine.

● 220V, 50Hz electrical energy is converted into 36KHz mechanical vibration, so as to achieve the purpose of rapid screening and net cleaning, making ultrafine powder screening easy.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!