首页>>product>>Dust free feeding station / Ton bag feeding station

Unit integration, diverse configuration

Model number:On-demand customization

yield:15-200 t/h

Use:It is suitable for plastic, rubber, food, medicine, chemical and other fields to unpack and unload dry powder and granular materials such as plastic resin and food additives.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

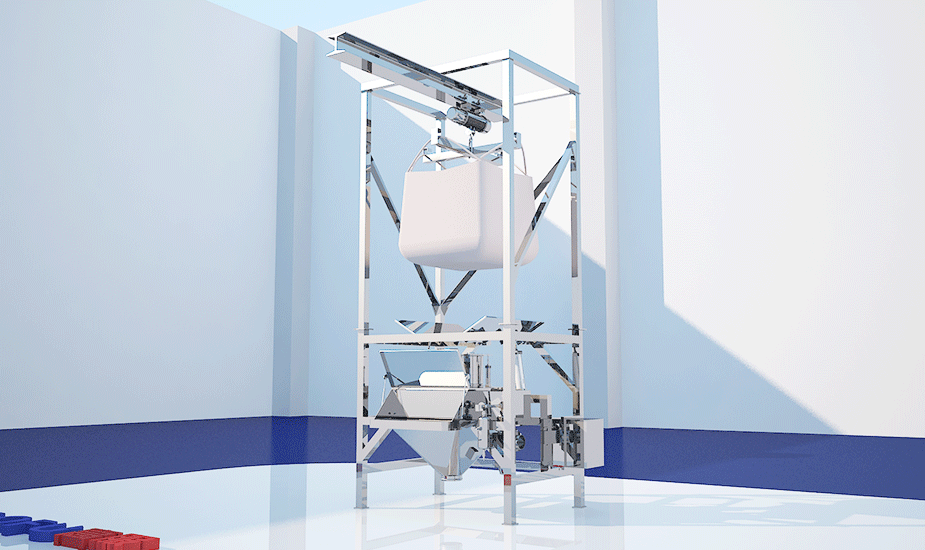

The ton bag unloader lifts the ton bag packing material to the feed port, opens the flow control valve and the attached vibration unloading device to promote the powder and granular material in the bag to fall into the lower hopper through the self-weight.

Suitable for all kinds of powder materials.

Ton bag feeding station is used to realize the unloading function of bagged bulk materials, which is a semi-automatic manual unpacking equipment. The packaging bag is lifted by the electric hoist, the rope of the packaging bag is hung on the steel bracket, the lifting and walking of the hoist are controlled by manual operation, and the lifting and walking are run along the walking guide rail to the top of the unloading area. The packaging bag is placed on the bracket tray, so that the large bag is in the unloading position. Then, manually open the operation door of the discharge valve, manually pull the discharge port of the bag into the tie of the discharge valve, press the bag tie button, the discharge valve bundle cylinder will lock the bag port, and then manually pull the discharge port of the large bag from the discharge position, cover the outer side of the discharge pipe in the discharge port sealing box, press the pneumatic control switch of the pressure bag mechanism to make the sealing flange lower. And firmly press the end of the discharge pipe, seal the discharge channel to prevent dust leakage during the discharge process, then manually unpack the bag, and then close the operation door. Manually open the valve on the ventilation dust collection line connected to the discharge port seal box. At this point, the discharge preparation process is complete.

Unloading process:

Manually open the tightening mechanism in the discharge valve, the discharge port of the packaging bag is opened, and the material starts to discharge along the pipeline chute under the action of gravity, and enters the discharge process.

During the discharge process, according to the process requirements of the whole system, the discharge valve bunching mechanism can be automatically or manually controlled to control the discharge process.

When the user is filled with material in the bin of the screw belt mixer, press the button of the large bag binding mechanism, tighten the discharge port of the large bag, and stop adding material to the mixer.

During the unloading process, in order to make the material flow smoothly in the packaging bag and pipe chute, auxiliary actions such as bag-beating mechanism are added, which can be operated automatically or manually.

Slapping and bagging action can also be controlled by PLC to carry out regular slapping and bagging movement, the action sequence is to slap the middle of the bag first, and then slap the bottom of the bag.

After the discharge is completed, open the operation door of the discharge valve, after the manual tying of the bag, the binding mechanism is loosened, the pressure bag mechanism is raised, and the manual operation of the electric hoist is lifted to lift out the empty bag.

Customized according to demand, no fixed model.

● Large bags of packaging materials are unloaded in a closed production system.

● Electric hoist or forklift is easy to transport tons to the unpacking station.

● Easy to take materials, materials flow in a closed space, no dust leakage.

● The flapping device helps the material flow out of the ton bag, and the vibration device can break the arch bridge.

● Can be used for a small amount of materials, can be used as storage bin.

● Can achieve volume measurement and weight measurement, automatic control system to achieve continuous unpacking.

● It can be made according to the explosion-proof requirements and customized according to the customer's site.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!