首页>>product>>Industrial Vibrating Screen / Swing screen

Unit integration, diverse configuration

Model number:GFBD-600 to 3200/Special models need to be customized

yield:15-500 t/h/output varies according to material characteristics

Use:Citric acid, milk powder, starch, sugar, vitamins, spices, tea, feed, plastics, rubber, fertilizers, sugar and salt industry, renewable resources, EPS, PVI, PVC, resin, etc.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

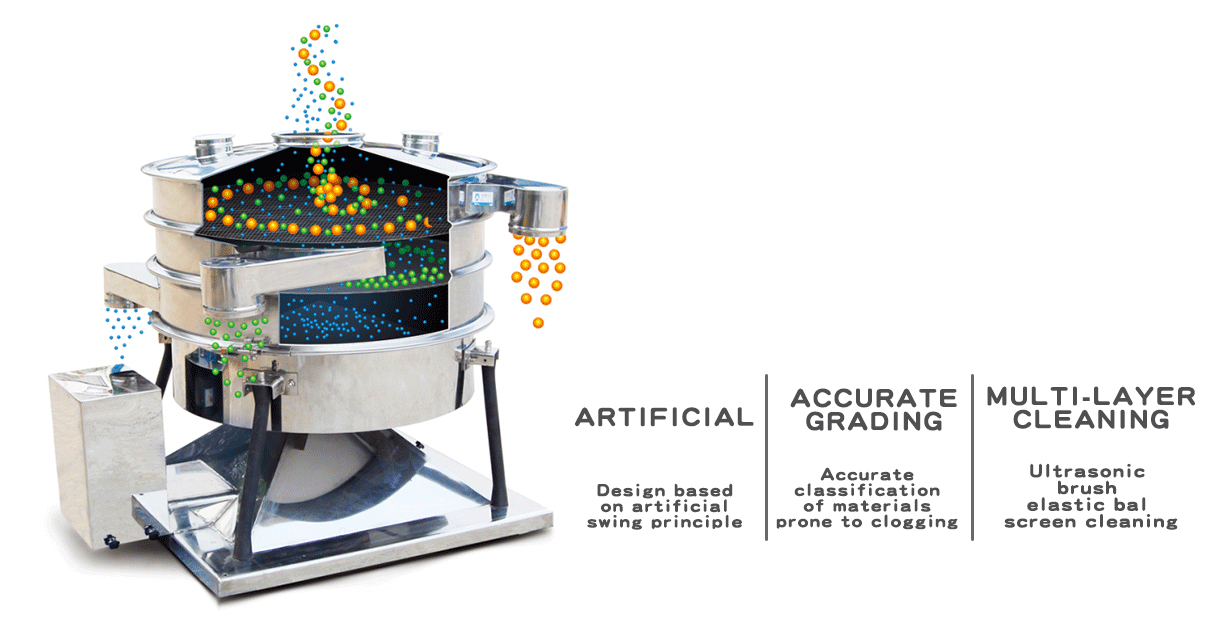

The swing screen, also known as the swing screen or circular swing screen, is a manual screening machine developed and manufactured by Gaofu based on the principle of manual screening. Gaofu's swing screen saves labor, has a large screening output and good precision, and has been well received and praised by users at home and abroad!

The swing screen is a low-frequency rotary vibrating screen that simulates artificial shaking. Its principle is that the instantaneous motion is the synthesis of radial displacement and circular motion with this displacement as the axis (spiral motion). The vibrator with adjustable eccentricity produces nonlinear three-dimensional motion, and the material also produces the same motion similar to manual operation, thereby achieving the purpose of screening. Combined with screening accessories, a more ideal screening effect can be obtained. It is suitable for round, cylindrical, sheet-shaped, and even regular-shaped materials that are easy to block the net and require fine screening.

| model | Effective screening diameter (mm) | Effective screening area (㎡) | Screen surface angle (°) | Layer Number (s) | power (kW) |

| GFBD-600 | Φ600 | 0.21 | 0-10 | 1-5 | 0.75 |

| GFBD-1000 | Φ1000 | 0.66 | 0-10 | 1-5 | 1.1 |

| GFBD-1200 | Φ1200 | 0.98 | 0-10 | 1-5 | 2.2 |

| GFBD-1600 | Φ1600 | 1.81 | 0-10 | 1-5 | 4 |

| GFBD-2000 | Φ2000 | 2.8 | 0-10 | 1-5 | 5.5 |

| GFBD-2400 | Φ2400 | 4.15 | 0-10 | 1-5 | 5.5 |

| GFBD-2600 | Φ2600 | 5.31 | 0-10 | 1-5 | 5.5 |

| GFBD-3200 | Φ3200 | 7.5 | 0-10 | 1-5 | 11 |

Single or multi-layer high-yield screening

Six particle sizes can be screened, with screen diameters ranging from 600mm (24 inches) to 2600mm (104 inches); small swing screens can be equipped with 4 screens, large ones can reach 5 layers, and provide 5 to 6 groups of classification. For single-classified products, our technology can achieve double or even higher production capacity on the same screen.

Screening efficiency and product yield

The principle of the swing screen is actually a mechanical simulation of human hand screening.

Gentle acceleration and low-speed operation ensure that the material always rolls on the surface of the screen. Especially for dry, low-density particles; it can also reduce the wear of the screen itself (especially the screen) by highly abrasive products.

Each layer of the screen realizes coarse and fine particle classification

The material is fed from the almost horizontally moving screen body and diverges to the periphery along the spiral curve. At the same time, the fine-particle product is forced to effectively pass through the screen surface with vertical acceleration.

Effectively reduce the breakage of fragile materials

Hand screens can give materials gentle treatment. GFBD oscillating screen reproduces the same movement and is used in various applications where particle breakage is prohibited, such as: coffee for spray drying of particles, powdered products for biopharmaceuticals, as well as milk powder and metal powders.

Easy and convenient operation

When the particle size of the product approaches 30 microns, the clogging of the mesh becomes an urgent problem to be solved. With our various cleaning systems, it will be solved. Cleaning balls, brush cleaning with independent gear drive, jet cleaning, super-cleaning and jet brush combination cleaning systems. Screening systems with partial or full jet cleaning are usually used for products with high viscosity or static electricity.

Low noise, low energy loss

Due to the simple modular design and low speed operation, the noise of GFBD oscillating screen is always kept at 60~70Db, ensuring smooth and quiet operation. Using TEFC motor, the drive of the small model is 0.25kW, and the large model weighing 2 tons only needs 5.5kW power.

Less maintenance cost

The main vulnerable parts include: screen, seal ring, rubber ball or brush.

Based on the drum principle, the screen is tightened on the screen frame by special glue or welding. The life of the screen is greatly extended due to the slow acceleration and low force.

Negligible dynamic base load

Each GFBD swing screen is adjusted to complete balance on a special device before leaving the factory. So at the user's site, it can be placed on a very high steel structure. Considering the complexity of the dynamic load, it is necessary to do another balancing commissioning before starting.

Effectively reduce maintenance time

Quick and simple disassembly and installation in as fast as 15 minutes, rarely repeated bearing lubrication, ensuring continuous operation of the equipment at full load 7*24 hours.

Dust-proof operation

In addition to the existing ventilation system on site, the GFBD swing screen does not require any auxiliary devices for air purification or dust collection. The system can be equipped with airtight and vacuum design, as well as chlorine purification, etc.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!