首页>>product>>Industrial Vibrating Screen / Standard test sieve

Unit integration, diverse configuration

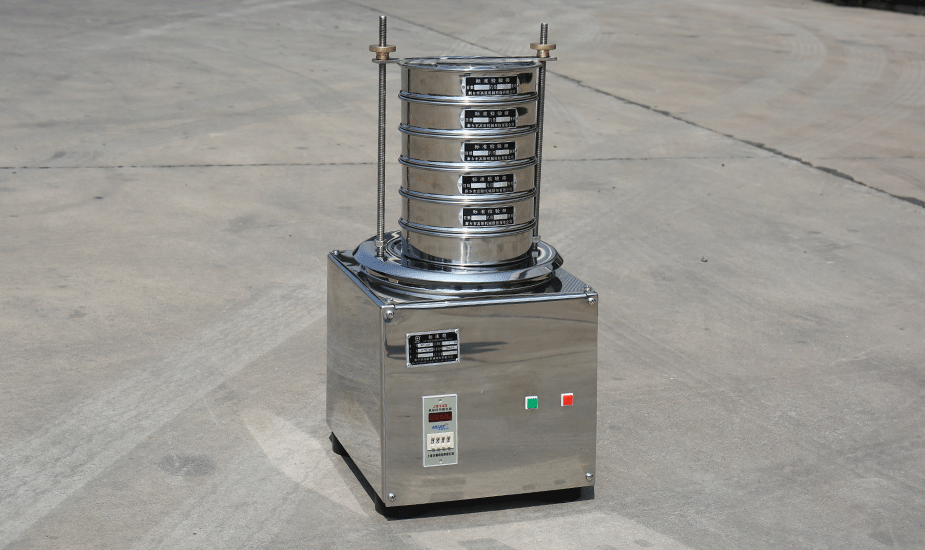

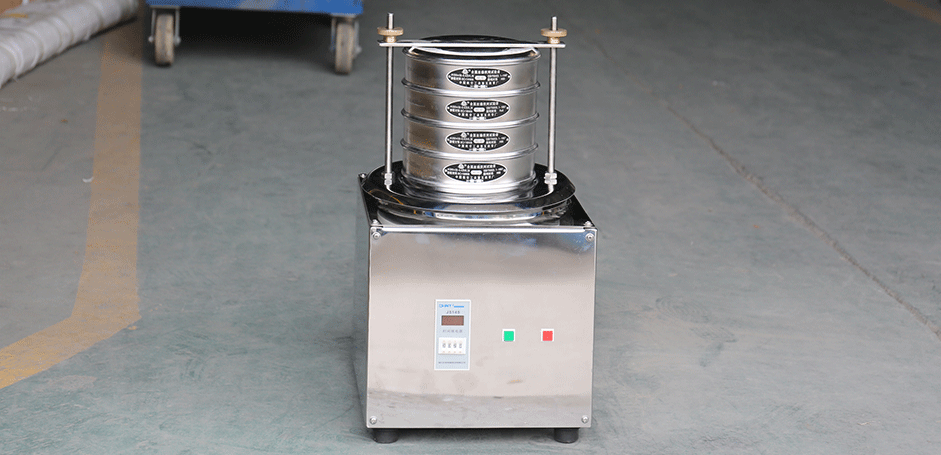

Model number:Φ200 (special models need to be customized)

yield:15-500 t/h (output varies according to material characteristics)

Use:Scientific research and production, laboratories, quality inspection rooms, and university laboratories in metallurgy, powder and particle, chemical industry, medicine, building materials, geology, na

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

The standard test sieve is a laboratory screening machine, also known as a test sieve, a sample sieve, or an analytical sieve. It is mainly used in university laboratories, research institutes, or some company laboratories. It is different from ordinary vibrating screening machines. It has national standards. The standard test sieve machine and the standard test sieve frame have certain standard restrictions.

The eccentric weights installed at the upper and lower ends of the motor shaft convert the motor's rotational motion into horizontal, vertical, and inclined three-dimensional motion, and then transmit this motion to the screen surface. The material will roll, rotate, and jump on the screen after being subjected to force; when used with standard screen grids, it can be used for vibration screening, filtration, standard testing, and other inspections and measurements of the particle size structure of granular and powdery materials, the solid content of liquids, and the amount of impurities.

| name | Numerical value |

| Sieve diameter(mm) | Φ200 |

| Number of sieve layers (s) | 5 |

| Vibration frequency (n/min) | 1400 |

| Amplitude of vibration(mm) | 1-4 |

| Exciting force (kN) | 3 |

| Chassis level(mm) | ≤0.6 |

| Motor power(kW) | 0.18 |

| Motor speed(r/min) | 1400 |

| External dimension(mm) | 370(long)×350(wide)×650(high) |

| Timing time (min) | 1-15 |

● The whole machine is small in size, light in weight, stable without vibration, noise, good sealing performance, dust-free and high in efficiency.

● Combined with the ultrasonic screening system, it has the function of automatically cleaning the screen, improving the screening efficiency and detection accuracy.

● High screening accuracy and accurate detection results. Suitable for particle shape, particle size distribution and various tests.

● It can be installed and used in three-dimensional multi-layer, flexible and convenient to move, and reliable for continuous operation.

● Adopting the standard inspection fixture of the state-owned No. 540 Factory, it has accurate detection and long service life.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!