首页>>product>>vibrating screen / Square swinging screen

Unit integration, diverse configuration

Model number:HXS-1536 to 2040

yield:15-500 t/h (output varies according to material characteristics)

Use:Dry mortar, machine-made sand, natural sand, quartz sand, perlite, dolomite, calcite, potassium feldspar and other stone powder and mineral powder; Metallurgy, metal powder, mineral powder, food, suga

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

The square swinging screen, also known as the rectangular swinging screen, is an efficient screening equipment with high precision and large output, which has excellent self-cleaning effect, high screen utilization rate and long life, and good sealing effect.

Square swing screen is widely used in chemical and new materials, metallurgy, metal powder, mineral powder, food, salt, sugar, abrasive, feed and other industries. The rotating motion of the exciter is transmitted to the screen surface through the square swinging vibrating screen, so that the material is quickly dispersed in the front of the screen machine, so as to achieve the purpose of efficient screening.

After the screen machine starts, the screen machine shaking body that is the screen box in the inertial force under the action of the reciprocating motion, the screen box drives the screen surface for periodic shaking, so that the screen surface of the material with the screen box for directional jumping movement, during which less than the screen surface aperture of the physical fall through the screen hole to the lower level, become the sieve, larger than the screen surface aperture of the material after continuous tumbling and jumping movement from the discharge port. To complete the screening work.

| Type number | Screen Size (m) | Screening area (㎡) | Screen Angle (°) | Number of screen layers (s) | Power rate (kW) | Allowable number of turns | Screen box travel (mm) |

| HXS-1536 | 1.5m*3.5m | 5.25 | 5.43±3 | 1~10 | 5.5 | 180-260 | 60-25 |

| HXS-1836 | 1.8m*3.5m | 6.3 | 5.43±3 | 5.5 | 180-260 | 60-25 | |

| HXS-2040 | 2.0m*4.0m | 8 | 5.43±3 | 7.5 | 180-260 | 60-25 |

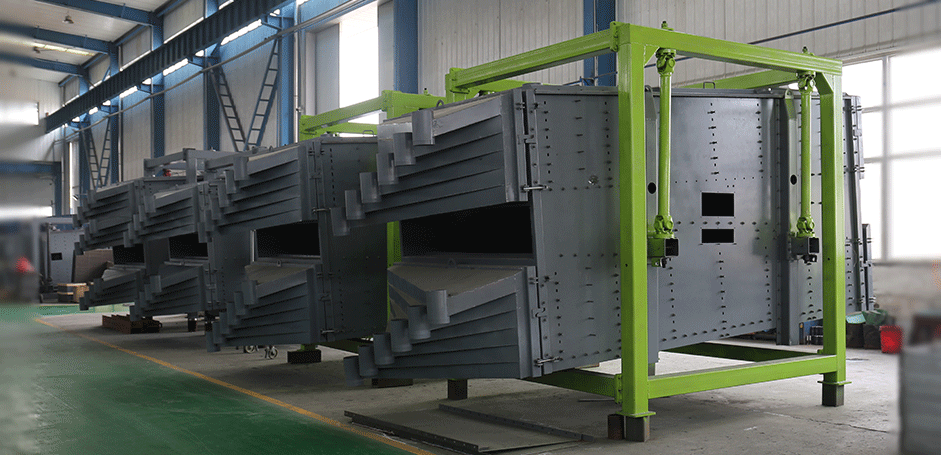

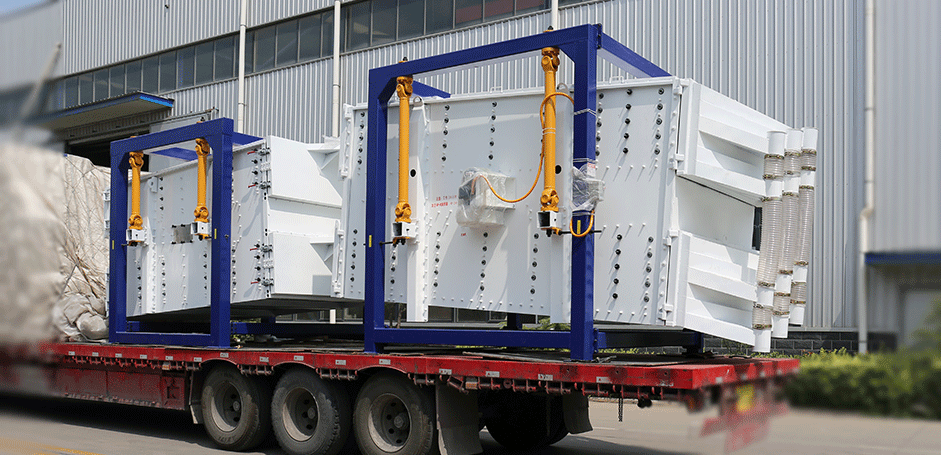

The square swinging screen adopts many new processes and standardized design schemes, which can be combined with the production situation and different customer needs to achieve a variety of combination modes. At the same time, the design concept also considers the convenience and safety of transportation, and the overall size of the equipment is designed in combination with the transport vehicle. Dust-proof cover and shaker force tray are made by a large press, which increases the strength and reduces the weight of the equipment. The plate is made of high-quality cold-rolled plate, which is more unique in mechanical design and achieves the design concept of high efficiency and energy saving.

● Large screen weight, unique multi-layer classification design, one machine is divided into two groups, one is used to multiple sets, the output is doubled.

● Completely closed structure, no dust flying, small vibration screen, low noise, in line with environmental protection requirements.

● Flexible screening, the acceleration is 4-5 times lower than the ordinary vibrating screen, and the service life is improved, thereby reducing maintenance costs.

● Network change is more convenient, simple operation, firm and reliable.

● Large electrostatic spraying process, the equipment is more beautiful, wear-resistant, rust prevention.

● Rotary screening: two layers of the same size screen, so that the material screened once again sieve, to achieve higher screening accuracy.

● Rotary reverse screening: material screening from fine → fine → medium → coarse way, coarse material plays a certain role in cleaning the mesh.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!