首页>>product>>Industrial Vibrating Screen / Slap vibrating screen

Unit integration, diverse configuration

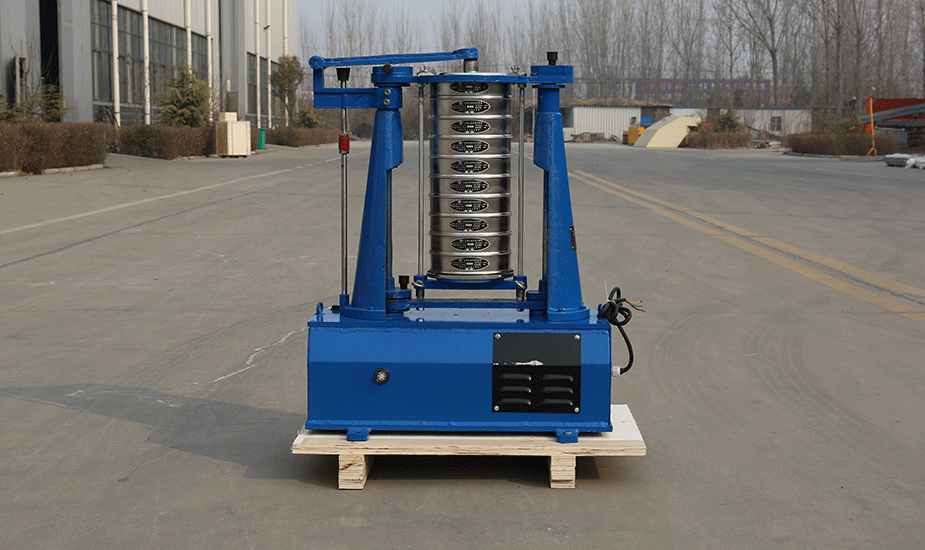

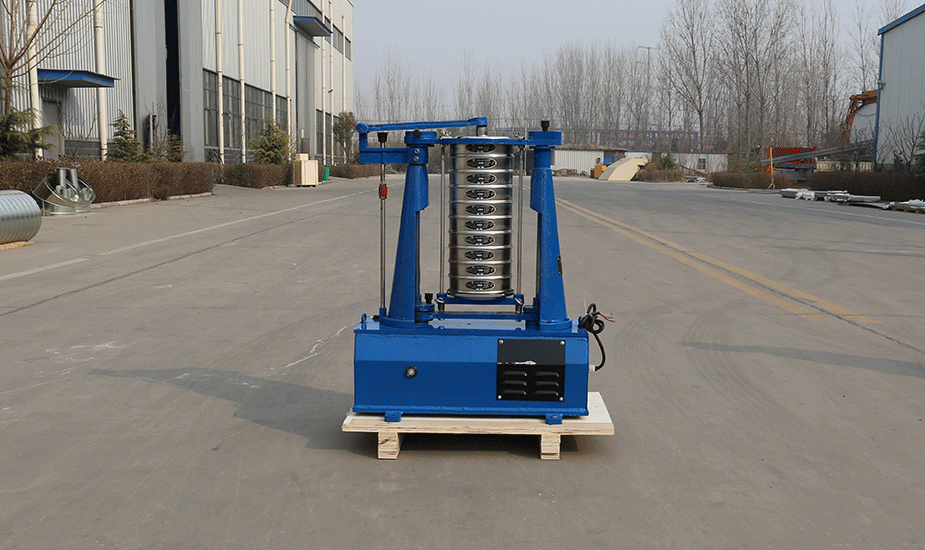

Model number:Φ200 (special models need to be customized)

yield:15-500 t/h (output varies according to material characteristics)

Use:Screening and testing of solid materials in scientific research and production laboratories of geology, metallurgy, powder, chemical industry, construction, cement, medicine, national defense and othe

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

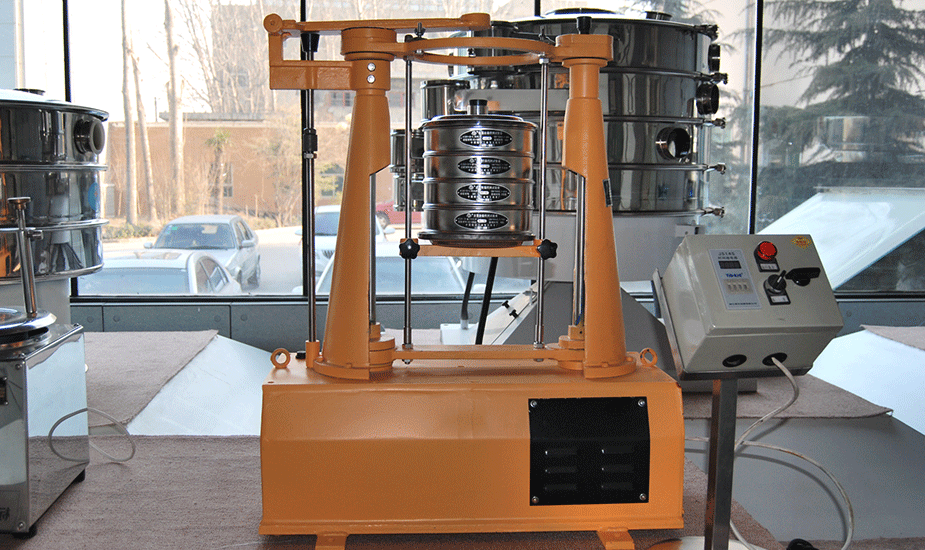

The slap type vibrating screen is sometimes also called the slap type standard vibrating screen, and is often used as a testing instrument in the laboratory. The slap type vibrating screen mainly consists of three parts, namely the base, the screen and the transmission device. The slap type vibrating screen can also be equipped with a variety of clamps, which are flexible and firm to clamp, and can be automatically shut down.

It is widely used in scientific research, production, and laboratories in geology, metallurgy, abrasives, powders, chemicals, construction cement, medicine, national defense and other departments to screen and test materials.

The power is driven by a Y series three-phase asynchronous motor. The power is transmitted through the coupling, driving the worm gear and worm speed change mechanism to move, respectively rotating the vertical shaft and the cam shaft, causing the horizontal circular motion of the screen, and at the same time driving the top rod to rise and fall to push the hammer to hit. The material is subjected to the force to produce a circular motion trajectory on the screen surface, and at the same time, it jumps and rolls due to the impact force of the hammer, and finally completes the screening process according to the size of the screen hole to achieve the purpose of inspection and classification.

| name | Numeric |

| Shaking times (times/min)Shaking times (times/min) | 290±5 |

| Number of taps (times/minute) | 110±4 |

| Slap height (mm) | 38±6 |

| Reciprocating stroke (mm) | 25 |

| Screen diameter (mm) | Φ200 Φ75 Φ100 |

| Sun-drying layer (s) | 5 |

| Motor power( W ) | 370 |

| Motor speed( mm ) | 1400 |

| Motor voltage( v ) | 380 |

| Dimensions(mm ) | 350(long)×450(Width)×785(high) |

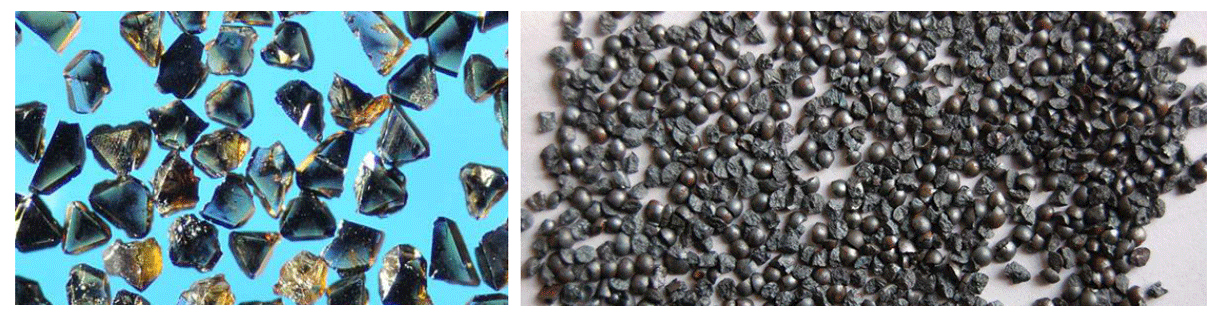

| gross weight(kg ) | 190 |

1. The slap-type vibrating screen can screen a variety of characteristic materials. It is suitable for checking the particle size composition of ordinary abrasives, superhard material production grading and particle size composition inspection. It is also widely used in scientific research, production, and laboratories in geology, metallurgy, abrasives, powders, chemicals, construction cement, medicine, national defense and other departments to screen and test materials. It is especially suitable for the production and grading process of diamond micropowder and superhard material industries, and is used repeatedly with high intensity and high frequency.

2. The slap-type vibrating screen is sometimes also called the slap-type standard vibrating screen, which is often used as a testing instrument in the laboratory. The slap-type vibrating screen mainly consists of three parts, namely the base, the screen and the transmission device. The slap-type vibrating screen can also be equipped with a variety of clamps, which are flexible and firm to clamp, and can be automatically shut down.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!