首页>>product>>Industrial Vibrating Screen / Rotary Vibrating Screen

Unit integration, diverse configuration

Model number:S49-600 to 2000/Special models need to be customized

yield:15-500 t/h/Product varies according to material characteristics

Use:Battery materials, silicon materials, food industry, pharmaceutical industry, chemical industry, metals, metallurgy and mining, non-metallic industry, other industries, etc.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

The rotary vibrating screen, also known as the three-dimensional vibrating screen and the circular vibrating screen, is a high-precision fine powder screening equipment developed, upgraded and manufactured by Gaofu Machinery after introducing foreign technology based on years of screening experience and feedback from domestic users. It is suitable for screening and filtering of materials such as particles, powders, and mucus. It is praised by domestic users for its high screening efficiency and convenient screen changing!

Lithium iron phosphate, ternary materials, graphite, polycrystalline silicon, monocrystalline silicon, sugar powder, starch,salt, rice flour, milk powder, soy milk, egg powder, soy sauce, juice,tea, brewed drinks, dairy products,candy, snacks, quick-frozen foods , condiments, proteins,food additives, industrial drugs, traditional Chinese medicine powder, granular pills, pellets, resins, coatings, cosmetics, paints, aluminum powder, lead powder,copper powder, ore, alloy powder, welding rod powder, manganese dioxide, Electrolytic copper powder, electromagnetic materials, grinding powder,refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, waste oil, waste water, dyeing and finishing waste water, papermaking, additives,activated carbon, etc.

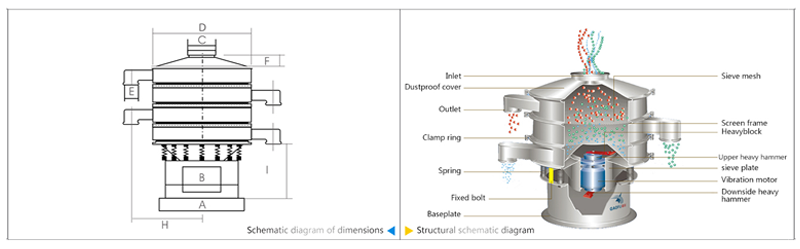

The rotary vibrating screen uses a vertical vibrating motor as the exciter. Eccentric weights are installed at the upper and lower ends of the vibrating motor to convert the rotating motion of the vibrating motor into horizontal, vertical and inclined three-dimensional motion, and then transmit this motion to the screen surface. By adjusting the phase angles at the upper and lower ends, the motion trajectory of the material on the screen surface can be changed.

Appearance size parameter table

| Model | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | H (mm) | I (mm) | Single layer height(mm) | Double layers height(mm) | Three layers height(mm) |

| S49-600 | 530 | 430 | 246 | 600 | 100 | 70 | 391 | 415 | 785 | 910 | 1040 |

| S49-800 | 680 | 580 | 246 | 800 | 125 | 80 | 514 | 430 | 855 | 1005 | 1155 |

| S49-1000 | 800 | 700 | 246 | 1000 | 150 | 95 | 615 | 430 | 865 | 1015 | 1065 |

| S49-1200 | 975 | 855 | 400 | 1200 | 180 | 100 | 717 | 550 | 1020 | 1170 | 1320 |

| S49-1500 | 1190 | 1050 | 400 | 1500 | 180 | 116 | 866 | 545 | 1090 | 1270 | 1440 |

| S49-1800 | 1580 | 1440 | 400 | 1800 | 200 | 150 | 1070 | 675 | 1230 | 1400 | 1570 |

| S49-2000 | 1800 | 1640 | 400 | 2000 | 200 | 190 | 1210 | 685 | 1280 | 1445 | 1615 |

Technical Parameters

| Model | Effective screening diameter(mm) | Effective screening area(m²) | Screen specifications (mesh/inch) | Number of layers(s) | Power(kW) | |

| Vibration Motor | Ordinary motor | |||||

| S49-600 | φ560 | 0.23 | 2-500 | 1-5 | 0.25 | 0.75 |

| S49-800 | φ760 | 0.42 | 1-5 | 0.55 | 1.1 | |

| S49-1000 | φ930 | 0.64 | 1-5 | 1.1 | 1.5 | |

| S49-1200 | φ1130 | 0.95 | 1-5 | 1.1 | 1.5 | |

| S49-1500 | φ1430 | 1.61 | 1-5 | 1.5 | 2.2 | |

| S49-1800 | φ1730 | 2.35 | 1-5 | 2.2 | 3 | |

| S49-2000 | φ1920 | 2.9 | 1-5 | 2.2 | 3 | |

1. Any particles, powders, and mucus can be screened within a certain range.

2. Screening can be as fine as 600 mesh or 0.02mm, and filtering can be as small as 5 microns.

3. Gradual screening can screen one to five layers of screens, and can perform two to six levels of sorting or filtering at the same time.

4. High efficiency, exquisite and durable design, easy to change the screen, simple operation, and convenient cleaning.

5. The impurities and coarse materials of the rotary vibrating screen are automatically discharged, and continuous operation can be achieved.

6. The mesh design allows the screen to be used for a long time and the screen can be changed quickly, only 3-5 minutes.

7. Small size, space saving, and easy to move.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!