首页>>product>>vibrating screen / Roller screen

Unit integration, diverse configuration

Model number:FGZS0806 to 1212

yield:15-500 t/h (output varies according to material characteristics)

Use:Boiler coal screening, coal screening for coal chemical industry, coal washing plant screening.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

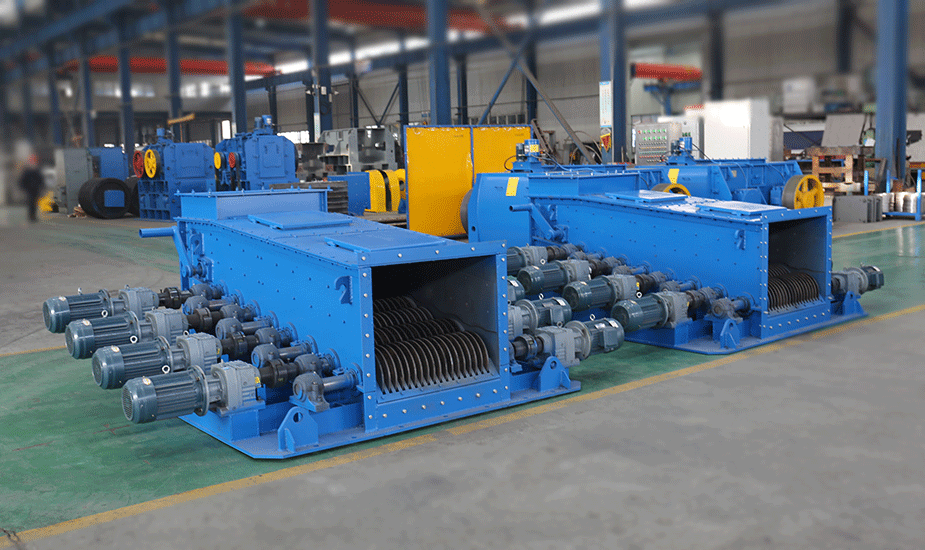

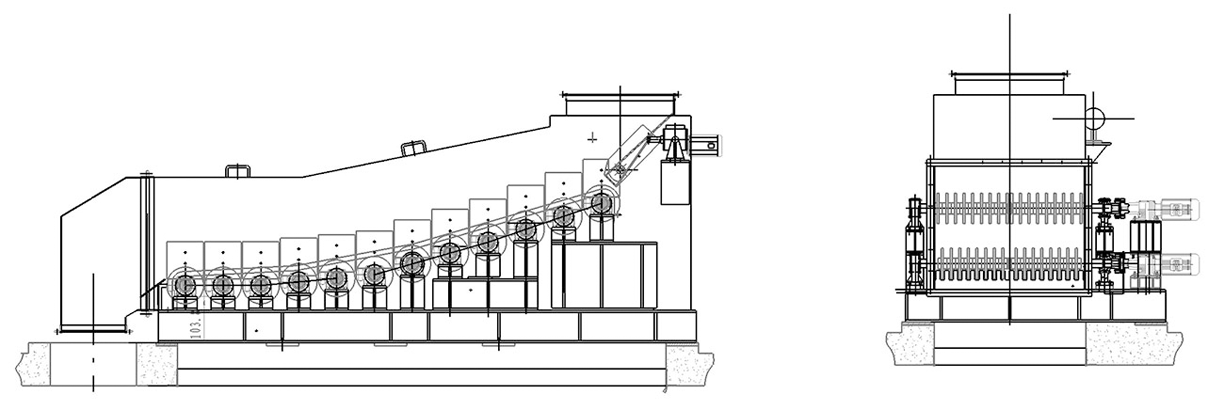

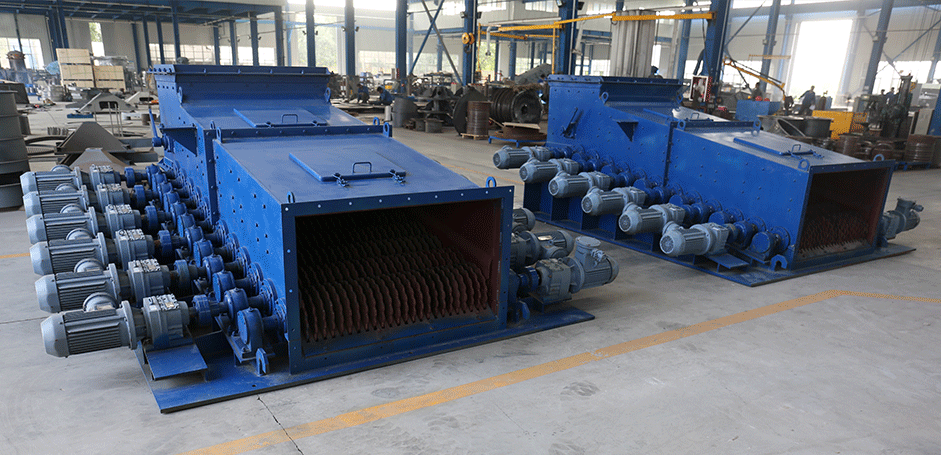

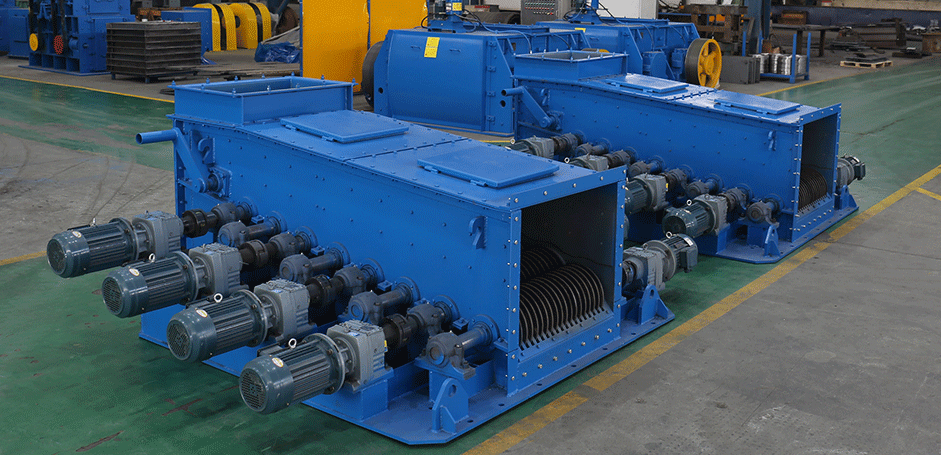

GZS roller screen produced by Gao Fu Co., LTD is one of the important equipment of boiler coal burning system and coal preparation system, which can be widely used in metallurgy, chemical industry, building materials and coal system, and is well received by the public. The screen surface of the GZS roller screen is composed of many parallel rolls, which are staggered with the screen disc, and the roller is rotated by the sprocket or gear transmission, and the direction of rotation is the same as the direction of the material flow. In order to loosen the material layer on the screen to facilitate penetration, the screen tray shape is eccentric and irregular. In order to prevent the material from jamming the screen shaft, a safety device is installed.

Because the screen shaft is arranged according to different working angles, the speed is faster when the material is running at a higher working Angle; When the material is running at a lower working Angle, the speed is more gentle. The material running at two different speeds begins to move axially when it meets at a certain position of the screen surface, and the screen surface can evenly arrange the material layer and effectively improve the screening efficiency.

| Type number | Production capacity (t/h) | Feed size (mm) | Discharge size (mm) | Number of axes | Power rate (kW) | Weight (kg) |

| GFGZS-0806 | 100~200 | 200 | 10~30 | 6 | 16 | 6000 |

| GFGZS-0808 | 100~200 | 200 | 10~30 | 8 | 21 | 7000 |

| GFGZS-1006 | 150~300 | 200 | 10~30 | 6 | 18 | 7000 |

| GFGZS-1008 | 150~300 | 200 | 10~30 | 8 | 21 | 8000 |

| GFGZS-1010 | 150~300 | 200 | 10~30 | 10 | 25 | 9500 |

| GFGZS-1012 | 150~300 | 200 | 10~20 | 12 | 30 | 11000 |

| GFGZS-1208 | 200~400 | 200 | 10~30 | 8 | 27 | 12000 |

| GFGZS-1210 | 200~400 | 200 | 10~30 | 10 | 35 | 13000 |

| GFGZS-1212 | 200~400 | 200 | 10~30 | 12 | 40 | 15000 |

● No vibration. Sieve shaft rolling screening, no vibrating screen plate screening.

● No noise. The equipment runs smoothly, the material less than the screen gap falls freely, and the material larger than the screen gap falls from the screen surface, without vibration and noise.

● No dust. The material does not beat on the screen surface and does not produce dust.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!