首页>>product>>vibrating screen / Pulverized coal vibrating screen

Unit integration, diverse configuration

Model number:MFS-1015 to 1224 (special models need to be customized)

yield:15-500 t/h (output varies according to material characteristics)

Use:Pulverized coal screening in blast furnace coal injection system of steel works.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

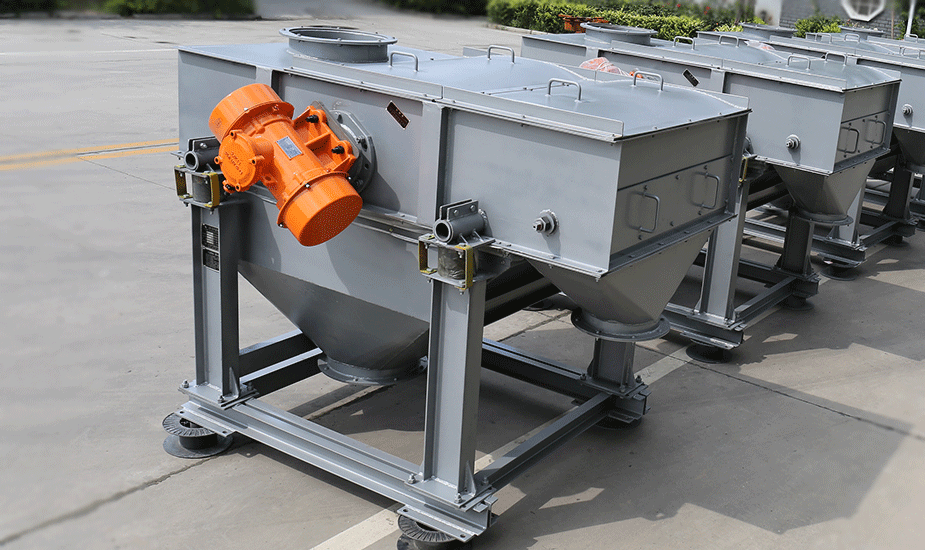

Pulverized coal vibrating screen, also known as blast furnace coal injection screen, used in steel blast furnace coal injection system pulverized coal screening, pulverized coal screening machine to remove the coal dust, woven bags, weeds and so on.

coal

Two explosion-proof vibration motors are used to stimulate the vibration source, so that the pulverized coal is thrown up on the screen, and at the same time, it moves forward in a straight line, and accurately intercepts the linear wood chips, woven bags, weeds and other debris in the pulverized coal through the screen, and automatically drains into the debris channel from the slag outlet. Coal injection process in which the finished coal powder is automatically discharged from the finished product discharge port to the lower channel through accurate filtration of the screen.

| Specification and model | Effective size of screen | Motor power | Effective yield |

| MFS-1015type | 1000*1500mm | 0.75kW*2 | 10~15t/h |

| MFS-1020type | 1000*2000mm | 1.1kW*2 | 15~20t/h |

| MFS-1224type | 1200*2400mm | 1.5kW*2 | 20~30t/h |

Easy to install, easy to operate. It is easy to match the original equipment improvements in the field.

The equipment is a net operation, and the material particle size is strictly controlled through the screen, which not only intercepts debris but also intercepts super-diameter materials into the system.

Completely closed structure, environmental protection and no dust. Automatic feed and discharge, fully meet the requirements of the field system.

The equipment is matched with explosion-proof vibration motor, the power of 2 motors is 1.5KW~3.0KW, saving energy and reducing consumption.

The equipment is equipped with explosion-proof electronic control device, which can be quickly controlled locally or remotely.

The equipment fully meets the explosion-proof requirements of the site and meets the production standards.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!