首页>>product>>Industrial Vibrating Screen / Particle square sieve

Unit integration, diverse configuration

Model number:GFP-515 to 825

yield:15-500 t/h (output varies according to material characteristics)

Use:Classification of various granular materials

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

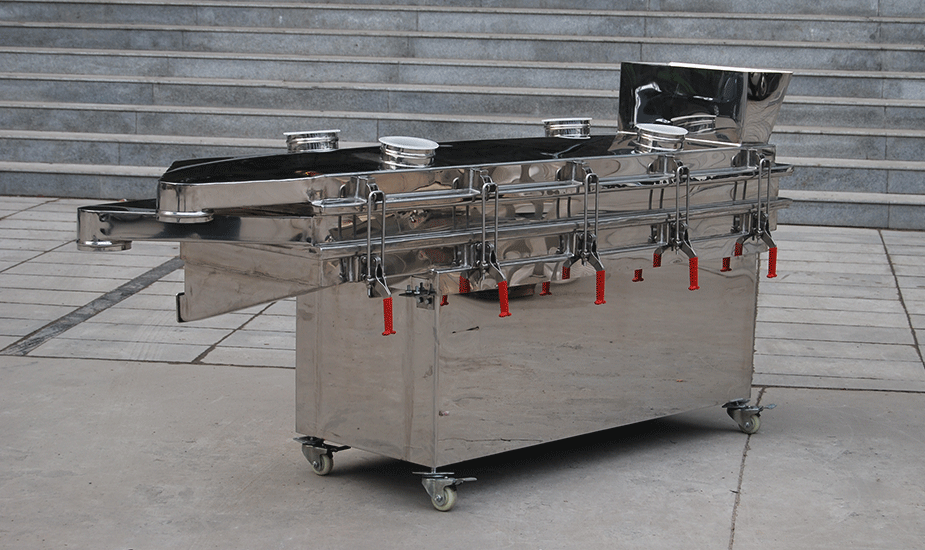

GFP series particle square screen is a quick-detachable linear vibrating screen designed and manufactured by Gaofu Company for the requirements of food, pharmaceutical and other industries. It can effectively remove lumps and fine powders generated by the production process to ensure uniform and complete particles. It has the characteristics of low energy consumption, high output, easy operation and good cleaning, fully enclosed structure, automatic discharge, suitable for 24-hour assembly line production.

GFP granule pill screen is the crystallization of Gaofu's years of experience in designing and manufacturing pharmaceutical screening equipment. It adopts the principle that the screen box is pulled by the motor shaft to produce a nearly circular motion. Granule pills roll forward on the screen surface, and granules and pills smaller than the mesh holes pass through the holes, while granules and pills with larger mesh holes are directly discharged. During the whole process, the material is evenly stressed and rolls smoothly, with almost no damage, and even the screening of wet pills can achieve the same effect.

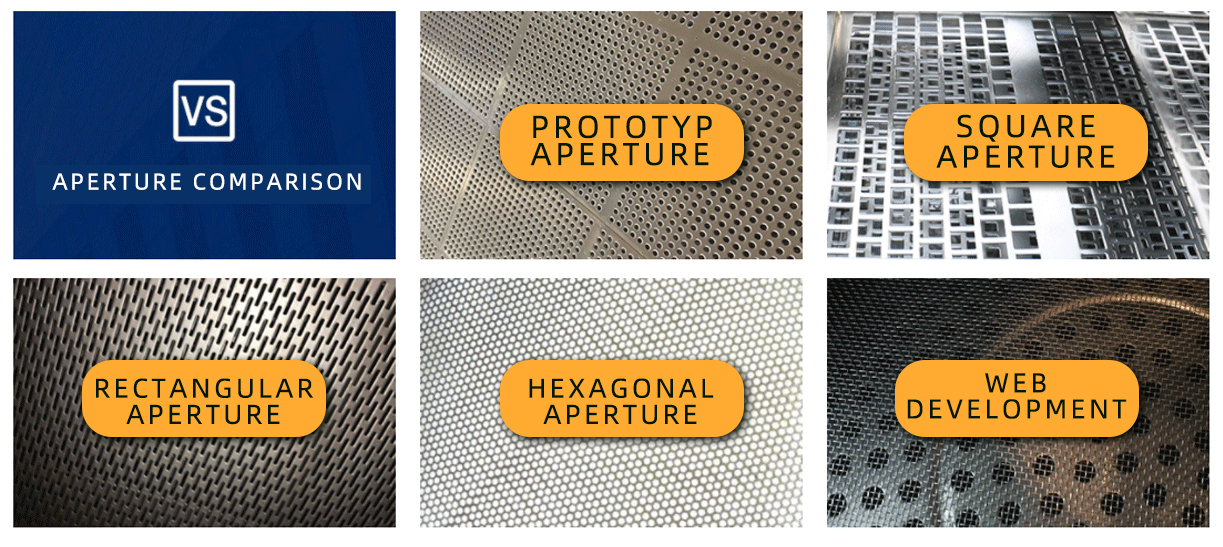

According to the specific data requirements of the material shape, different models are used, different screen frames are configured, and the screening apertures, slit plates, woven meshes, round, square, and hexagonal shapes are selected.

| model | Dimensions (mm) | Material size (mm) | Screen surface inclination (°) | Amplitude (mm) | Number of layers(s) | Power (kW) |

| GFP-515 | 500×1500 | 0.25~15 | 0°~7° | 1~8 | 1~3 | 2x(0.15~0.25) |

| GFP-520 | 500×2000 | 2x(0.15~0.25) | ||||

| GFP-615 | 600×1500 | 2x(0.15~0.25) | ||||

| GFP-620 | 600×2000 | 2x(0.25~0.4) | ||||

| GFP-820 | 800×2000 | 2x(0.4~1.1) | ||||

| GFP-825 | 800×2500 | 2x(0.75~1.1) |

● By using it in conjunction with the feeder, the material enters the screening machine evenly, making the material screening accuracy higher.

● According to the particularity of each material, a special screen is formulated, which does not block or jam, and the screening output is increased.

● The unique amplitude and frequency design method prevents the dry pills from breaking, the wet pills from deforming, and the particles and powders are well separated.

● Low energy consumption, high output, easy operation, easy cleaning, fully enclosed structure, automatic discharge, suitable for assembly line production.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!