首页>>product>>vibrating screen / Linear screen

Unit integration, diverse configuration

Model number:SZF-520 to 1540/Special models need to be customized

yield:15-500 t/h (output varies according to material characteristics)

Use:Dry mortar, machine-made sand, natural sand, quartz sand, perlite, dolomite, calcite, feldspar, refractory materials, petroleum coke, crushed tires, activated carbon and other stone powders, mineral p

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

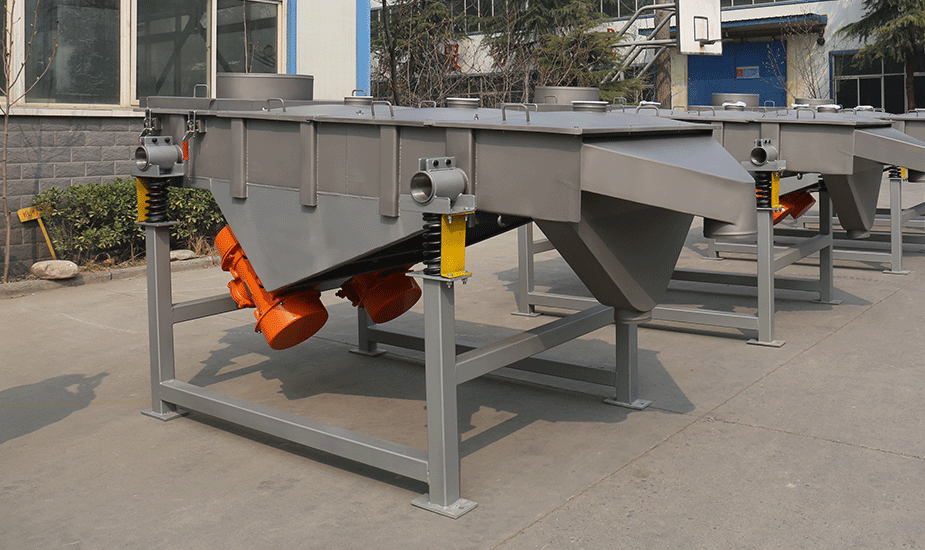

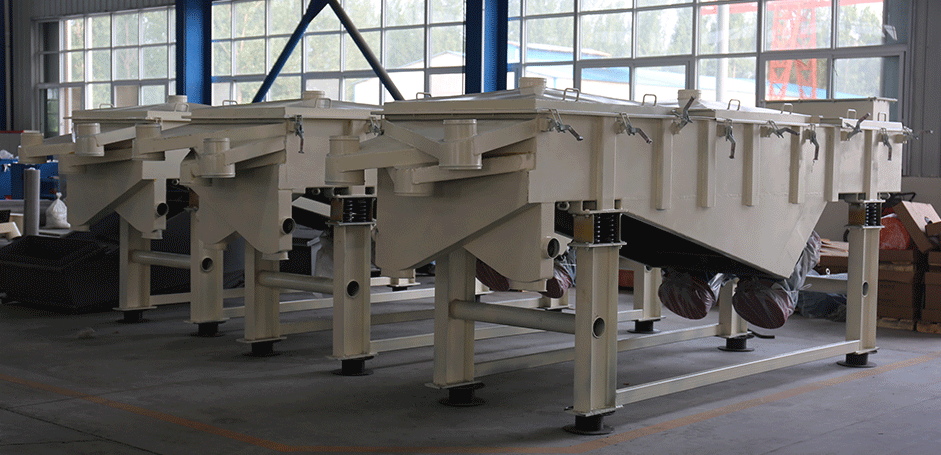

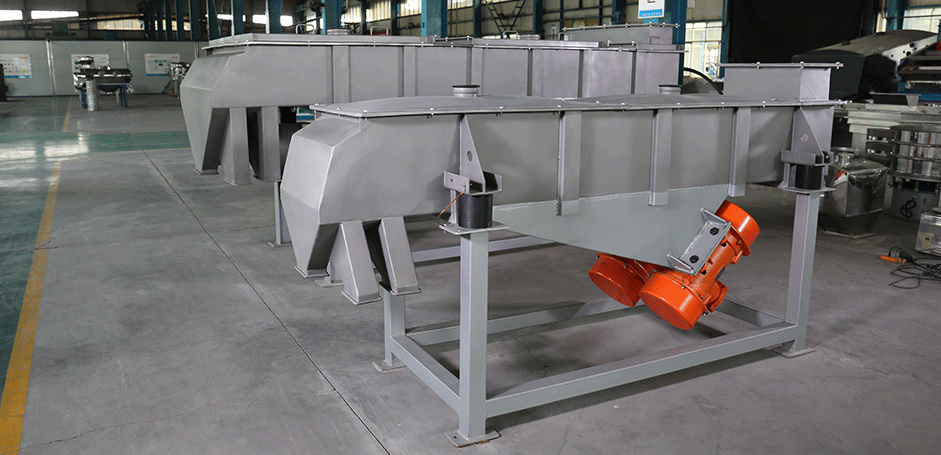

Linear screen manufacturer Gaofu has been focusing on the research and development and manufacturing of linear screening machines for more than 30 years. The straight vibrating screen, also known as the rectangular vibrating screen, is widely used in the grading and screening of machine-made sand, natural sand, quartz sand and other stone powder, mineral powder and granular materials.

When the two vibration motors installed longitudinally on the screen body are running relatively to each other, the lateral exciting forces generated by the motors are offset by each other due to the relative running of the motors, and the longitudinal exciting forces are transmitted to the entire screen box through the vibration transmitting body, causing the screen surface to vibrate, so that the materials on the screen surface are affected by the exciting forces and jump on the screen surface toward the discharge direction. Materials smaller than the screen holes pass through the screen holes and fall to the lower layer, and flow out from the discharge port after continuous jumping. Due to the reasonable screening process, materials with several different particle sizes can be obtained after being graded by the vibrating screen, thus completing the material grading operation.

| model | Nominal size (mm) | Material size (mm) | Incline angle (°) | Amplitude (mm) | Number of layers(s) | Power (kW) |

| SZF520 | 500×2000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.4~0.75) |

| SZF525 | 500×2500 | 2×(0.4~0.75) | ||||

| SZF530 | 500×3000 | 2×(0.75~1.1) | ||||

| SZF535 | 500×3500 | 2×(0.75~1.1) | ||||

| SZF1020 | 1000×2000 | 2×(0.75~1.5) | ||||

| SZF1025 | 1000×2500 | 2×(1.1~1.5) | ||||

| SZF1030 | 1000×3000 | 2×(1.5~1.8) | ||||

| SZF1035 | 1000×3500 | 2×(1.5~2.2) | ||||

| SZF1040 | 1000×4000 | 2×(1.5~2.2) | ||||

| SZF1225 | 1200×2500 | 2×(1.5~2.2) | ||||

| SZF1230 | 1200×3000 | 2×(1.8~3) | ||||

| SZF1235 | 1200×3500 | 2×(1.8~3) | ||||

| SZF1530 | 1500×3000 | 2×(2.2~3) | ||||

| SZF1535 | 1500×3500 | 2×(2.2~3) | ||||

| SZF1540 | 1500×4000 | 2×(2.2~4) |

● Various materials can be graded and screened, and the particle size after screening is uniform and the screening accuracy is high.

● Generally, a single unit is designed with 1-5 layers, and the required number of layers can be selected according to different needs.

● It has the advantages of convenient maintenance and relatively low probability of repair.

● The angle-adjustable excitation source is used to screen cleanly; multi-layer design can be used to screen more; negative pressure can be evacuated, and the environment is good.

● It has a unique effect on the screening and grading of powdery and granular materials.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!