首页>>product>>Industrial Vibrating Screen / Fully automatic self-cleaning vibrating screen

Unit integration, diverse configuration

Model number:TSS-4S (special models need to be customized)

yield:15-500 t/h (output varies according to material characteristics)

Use:Used for recycling paper sizing materials

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

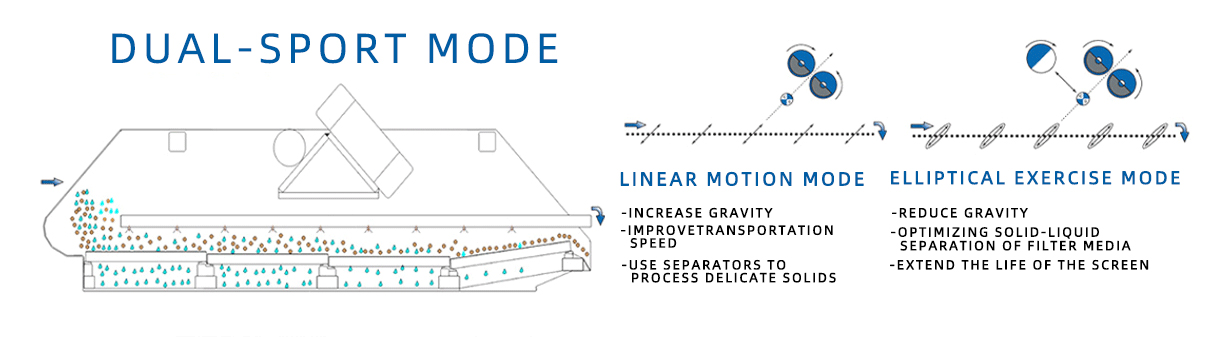

The fully automatic self-cleaning rectangular vibrating screen is specially designed by Gaofu for solid-liquid separation. It is used for the recycling of paper sizing materials. This equipment solves the problem of sizing material recycling and meets the needs of papermaking enterprises for the recycling and application of sizing materials of membrane transfer sizing machines. There is no doubt that Gaofu rectangular vibrating screen performs well in the transportation and recycling of sizing materials. The revolutionary dual motion mode includes elliptical motion and linear motion. This innovative design allows the operator to switch between the two motion modes directly during the operation of the machine, thereby meeting the screening requirements of different materials.

Used for recycling paper sizing materials

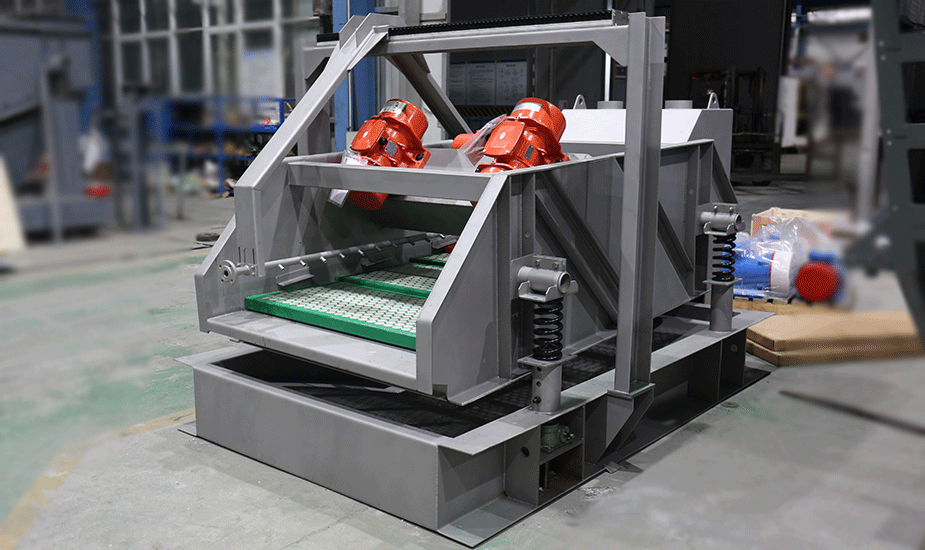

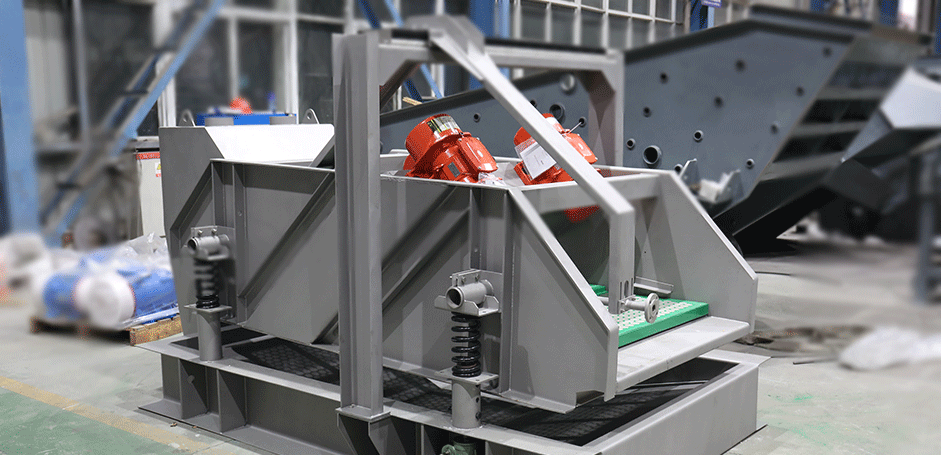

The fully automatic self-cleaning rectangular vibrating screen (TSS-4S) uses the principle of vibration motor excitation to make the material move in an elliptical and linear manner on the screen surface, and the reasonably matched screen and spray mechanism reciprocate to wash the screen surface to achieve the purpose of screening. It has stable vibration, noise reduction, simple operation and good screening performance.

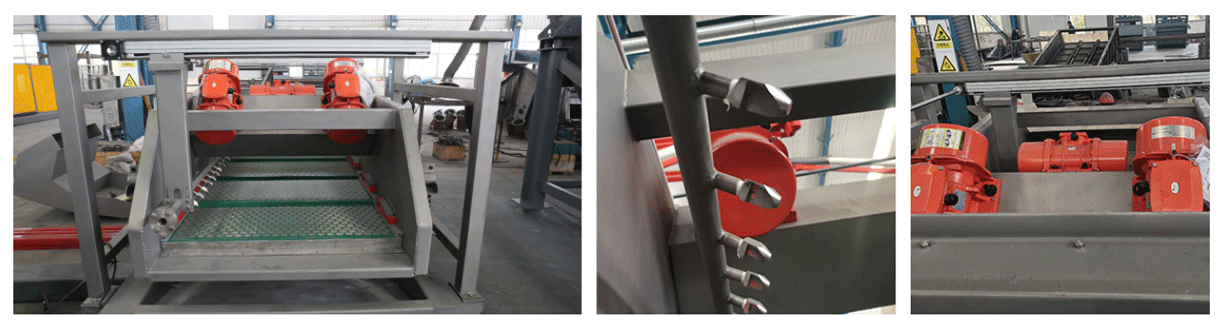

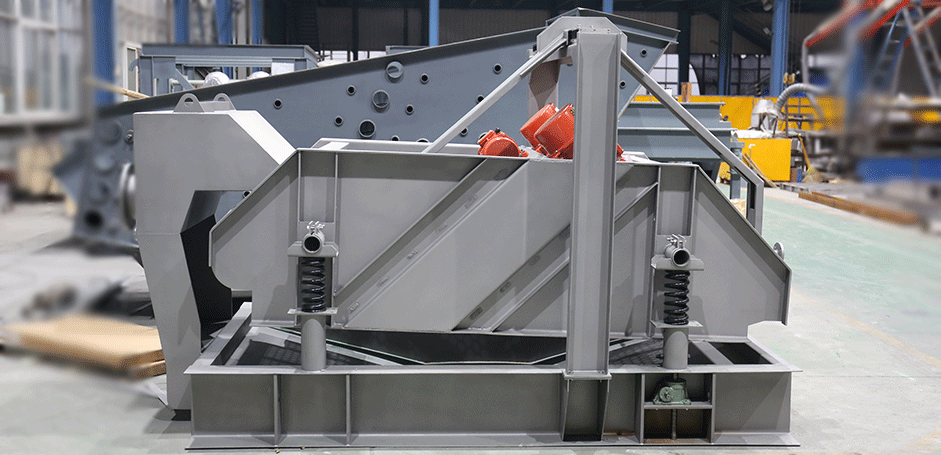

The fully automatic self-cleaning rectangular vibrating screen (TSS-4S) is mainly composed of a screen box, a screen mesh, a vibration motor, a motor pedestal, a vibration damping spring, an angle lifting device, a bracket, a reducer, a spray mechanism, etc.

1. Screen box: It is welded from several steel plates of different thicknesses. It has certain strength and rigidity and is the main component of the vibrating screen.

2. Screen: It is composed of a high-strength frame and two layers of 316L stainless steel wire mesh.

3. Vibration motor: equipped with 2 1.0KW24KN and 1 0.4KW11KN motor.

4. Spraying mechanism: When working, the spraying mechanism is opened, and the spraying water flushes the mesh surface back and forth, so that the screen can achieve a better filtering effect.

| 型 号 | 尺寸(CM) | 进口尺寸 | 出口尺寸 | 处理量(m³/h) | 筛网数量 | 筛网精度(目) | 筛面倾角 | 振次(次/分) |

| 高服TSS-4S | 300×170×220 | DN250 | DN300 | 70-110 | 4 | 70-110 | 0-7° | 960 |

Gaofu's breakthrough design allows the device to use linear motion when encountering high volume solids. In these intervals, the separator needs to generate a large gravity force to effectively move dense solids through the screen. As conditions change, the device can adjust on the fly, flicking a switch on the control box to reconfigure the motion from linear mode to elliptical mode, providing longer screen residence time, producing drier solids, increasing screen life and reducing operating costs.

Gaofu rectangular vibrating screen equipped with a traveling spray system vibrating screen attachment can continuously clean the screen, leaving no solid fiber residue on its surface. The blind holes created by the double-layer screen are the main reason for reduced capacity, and the traveling spray system can make the vibrating screen work more efficiently.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!