首页>>product>>vibrating screen / Fine sand recovery machine

Unit integration, diverse configuration

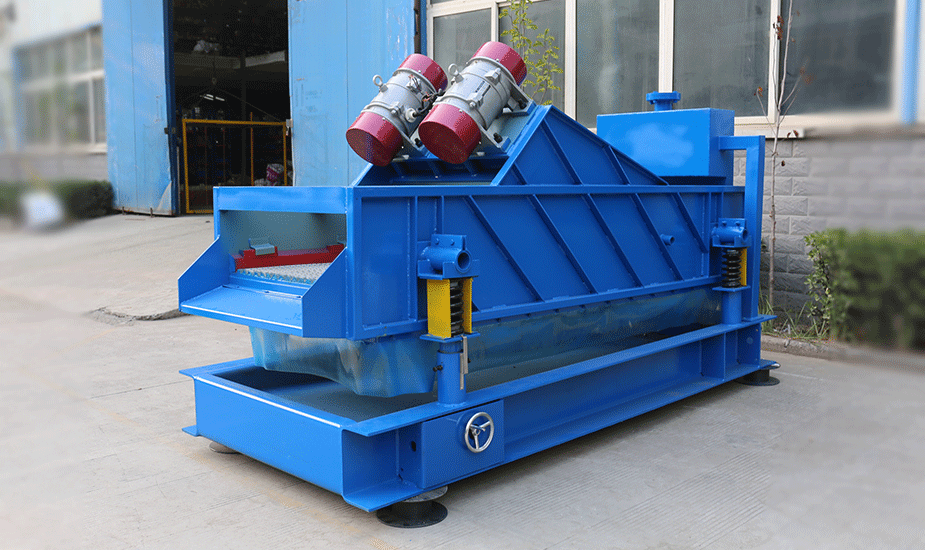

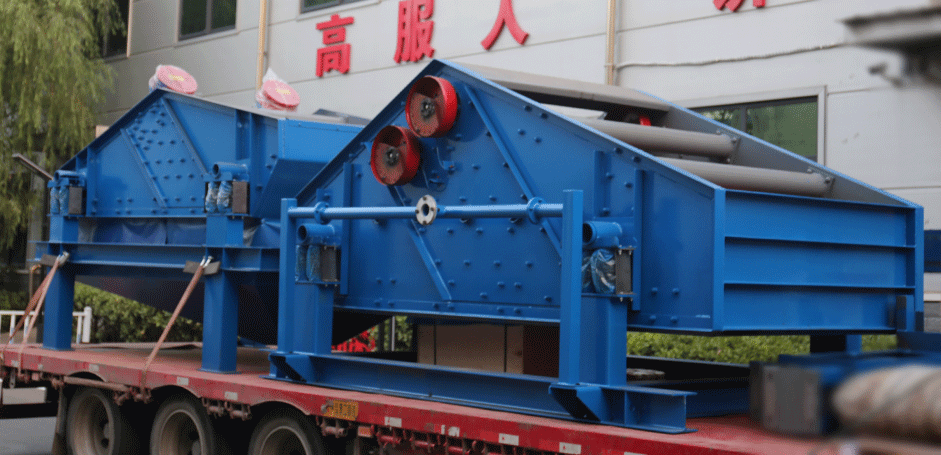

Model number:GFVD1036 to 2538 (Special models need to be customized)

yield:15-500 t/h (output varies according to material characteristics)

Use:The dewatering link of the ceramic raw material processing system, the tailings recovery and treatment of the concentrator, the processing system of quartz sand, the processing system of the sand and

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

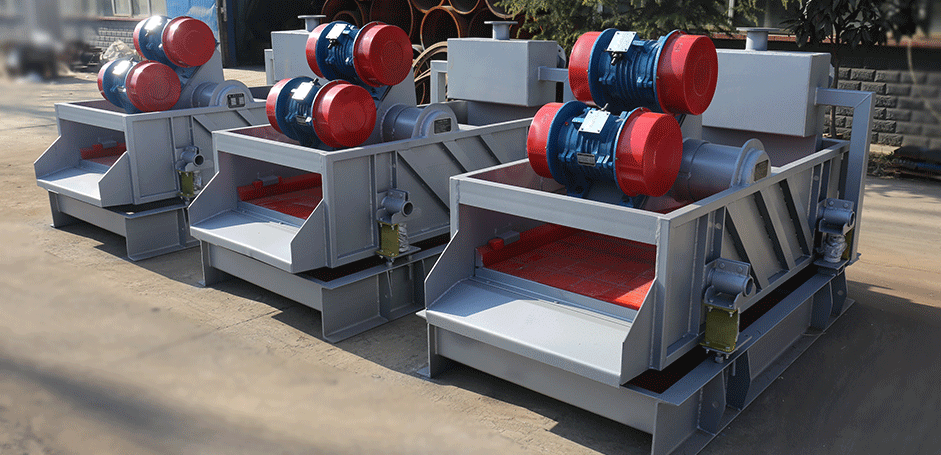

The fine sand recovery machine is a equipment developed for the dehydration, desliming and desliming of slurry materials. The feature of this machine is that it can solve the fine sand loss problem in sand making industry. Fine sand recovery machine is also known as tail sand recovery machine, fine sand extraction machine, fine sand collection machine, sediment separator, mud separator, sand water mixture treatment system.

At present, most of the artificial sand production lines basically use the wet production process, and no matter what kind of sand washing machine equipment is used, it will cause the loss of granular sand above 0.16mm, which not only has serious losses, but also seriously affects the gradation of sand, resulting in unreasonable gradation, the fineness modulus is coarse, and greatly reduces the product purity and quality of machine-made sand. At the same time, too much fine sand discharge will cause environmental pollution.

In order to solve the above problems, our company has successfully developed the fine sand recovery machine, which is an advanced level of fine material extraction equipment designed by our company to absorb foreign advanced technology and combine with the actual situation of sand powder, and is widely used in the sand aggregate processing system of hydropower station. Glass raw material processing system, artificial sand production line, recovery of coarse coal slime in coal preparation plant and environmental protection project (mud purification) can solve the problem of fine sand recovery.

It is used for mud purification, sand aggregate system of hydropower station, glass raw material processing system, artificial sand production line and recovery of crude coal slime in coal preparation plant.

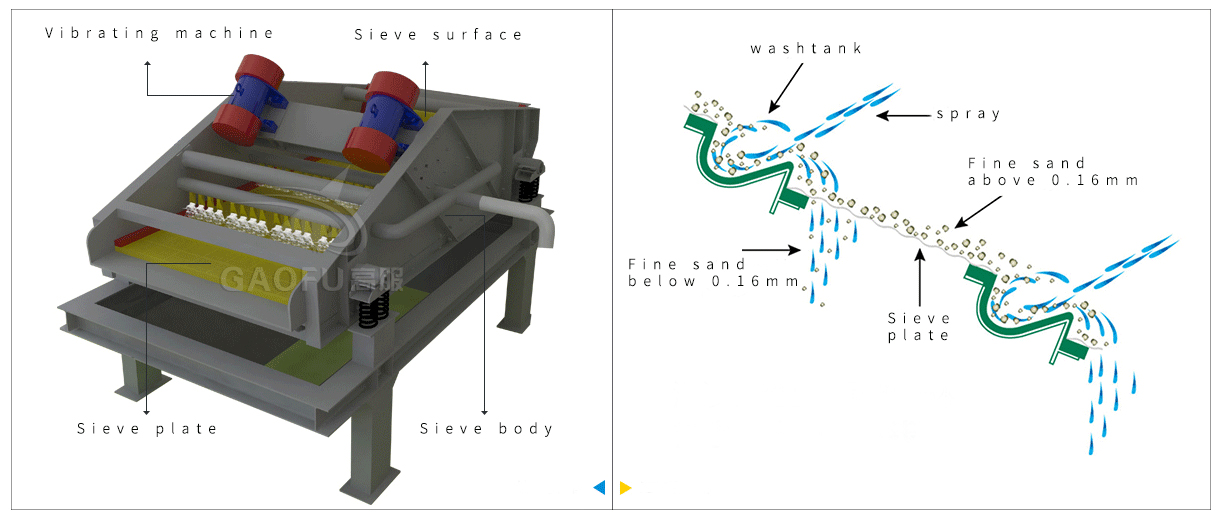

After the sand water mixture is transported to the high pressure separator by the vacuum high pressure pump, the fine sand separated by centrifugal force is provided to the vibrating screen through the sand settling nozzle, through the dehydration of the vibrating screen, the fine sand and water are separated, a small amount of fine sand, mud, etc. are returned to the cleaning tank, when the liquid surface in the cleaning tank is higher than the discharge port, the excess waste water is discharged back through the discharge port. Linear vibrating screen recovered material weight concentration of 70%-80%. Adjusting the fineness modulus can be achieved by changing the speed of the pump, changing the mortar concentration, adjusting the overflow water and replacing the sand nozzle. To complete the three functions of cleaning, dehydration and classification.

| Model number | Screen Angle (°) | Common screen size (mm) | Feed rate (t/h) | Power consumption (kW) | Reference total weight (t) |

| GFVD1036 | -5~-3 | 0.3~0.6 | 10~35 | 2 ×1.1 | 3.8 |

| GFVD1236 | -5~-3 | 18~65 | 2 ×2.4 | 4.5 | |

| GFVD1536 | -5~-3 | 30~90 | 2 ×3.1 | 5.7 | |

| GFVD1838 | -5~-3 | 40~120 | 2 ×7.5 | 6.6 | |

| GFVD2138 | -3~0 | 60~150 | 2 ×7.5 | 8.2 | |

| GFVD2538 | -3~0 | 80~200 | 2 ×11 | 11 |

● Can reduce the loss of spun yarn, so that it is controlled within 5-10%, a good solution to the artificial aggregate processing system of finished sand spun yarn modulus is high, low stone powder content of the problem.

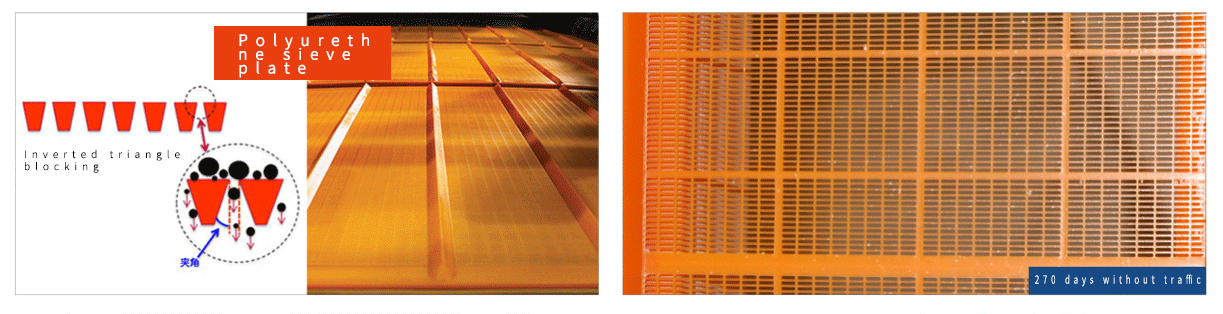

● Polyurethane screen, polyurethane screen than other types of screen longer life, and not easy to plug holes.

● The cyclone is lined with polyurethane, which improves the service life of the whole device, and can successfully complete the slurry concentration, liquid clarification and other work.

● Can recover 85% of the total emissions of fine particulate materials, with other equipment unparalleled technical and economic advantages.

● Yarn recovery system reduces the natural stacking time of fine materials, and can be directly transferred to the market.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!