首页>>product>>Vibrating conveyor / Electromagnetic vibration feeder

Unit integration, diverse configuration

Model number:No fixed model, customized according to demand

yield:15-500 t/h (output varies according to material characteristics)

Use:Food industry, pharmaceutical industry, chemical industry, abrasive industry, non-metallic industry, other industries, etc

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

Electromagnetic vibration feeder is a kind of equipment that implements the automation of flow operation. The electromagnetic vibration feeder is used to supply the material evenly or quantitatively from the storage bin or other storage equipment to the receiving equipment, which is the automatic feeding equipment for flow operation. For the quantitative or continuous supply of bulk, granular or powdery materials. Widely used in mining, metallurgy, coal, electric power, chemical, food, glass, refractory and other industries.

Rock sugar, potato chips, cocoa beans, tablets, medical powder, medical particles, quartz sand, zirconium corundum, silicon carbide, plastic particles, rubber powder, PVC particles, etc

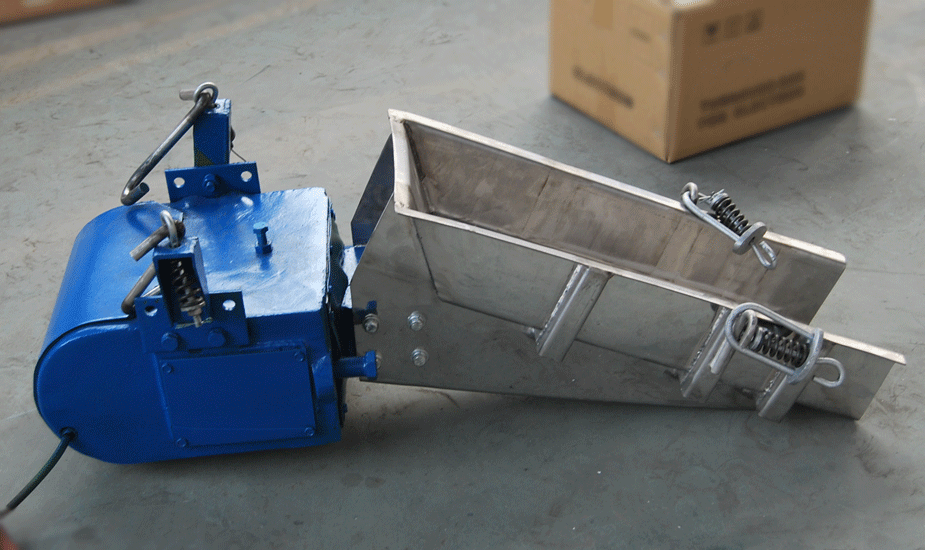

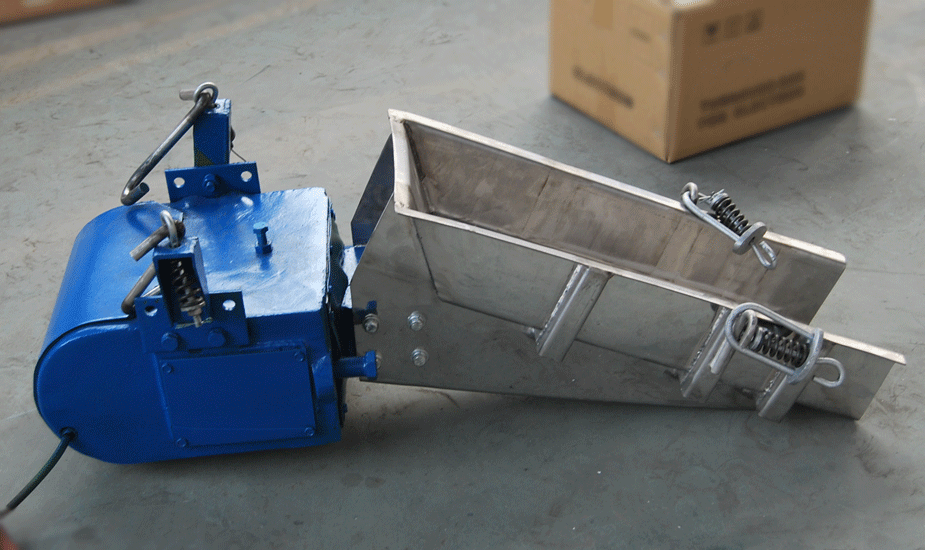

The feeding process of the electromagnetic vibration feeder is realized by using the electromagnetic vibrator to drive the feeding groove to move periodically along the inclined direction. When the vertical component of the acceleration of the vibration of the feeder is greater than the acceleration of gravity, the material in the groove will be thrown up, and the jumping movement will be carried out forward according to the trajectory of the parabola, and the throwing and falling will be completed in 1/5 seconds. Each time the material in the tank vibrates, the tank body vibrates at a frequency of 3000 times per minute, and the material is thrown forward to jump accordingly, so that the material moves forward evenly and continuously to achieve feeding.

Electromagnetic vibration feeder is a relatively complete two-particle directional forced vibration elastic system, the whole system works in a low critical resonance state, the main use of electromagnetic exciter to drive the tank body with a certain Angle to do reciprocating vibration, so that the material moves along the tank. The material is placed on the feeding tank body supported by the main vibration spring, the armature is connected with the main vibration spring of the tank body, and the coil is wound on the iron core. Due to the one-way pulsating current flowing through the coil after half wave rectification, the electromagnet generates the corresponding pulse electromagnetic force. In the positive half cycle of AC, the pulsating current flows through the coil and generates a pulsating electromagnetic attraction between the iron core and the armature, which makes the tank move backward, deforms the main spring of the exciter and stores potential energy. In the negative half cycle, no current passes through the coil, the electromagnetic force disappears, and the armature is separated from the electromagnet under the action of the spring force, so that the trough moves forward, so that the trough continuously vibrates with the frequency of AC power supply.

No fixed model, customized according to demand

● No rotating parts do not need lubrication, easy maintenance, low operating costs.

● Due to the use of the resonance principle of mechanical vibration, the double body works in a low critical near resonance state, thus consuming less electric energy.

● Because the feed flow can be changed and opened and closed instantaneously, the feed amount has a high accuracy.

● Can realize the centralized control and automatic control of the production process.

● The chute made of alloy steel plate can be used to transport high temperature, serious wear and corrosive materials.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!