首页>>product>>Dust free feeding station / Clean feed station

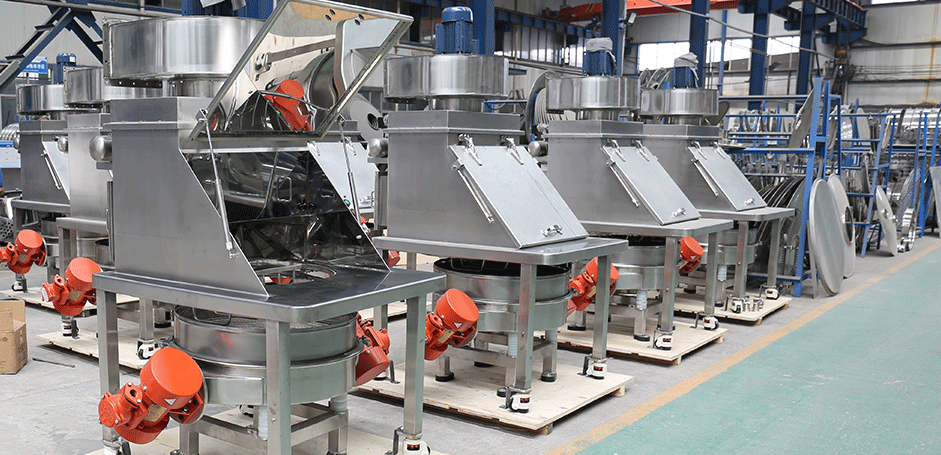

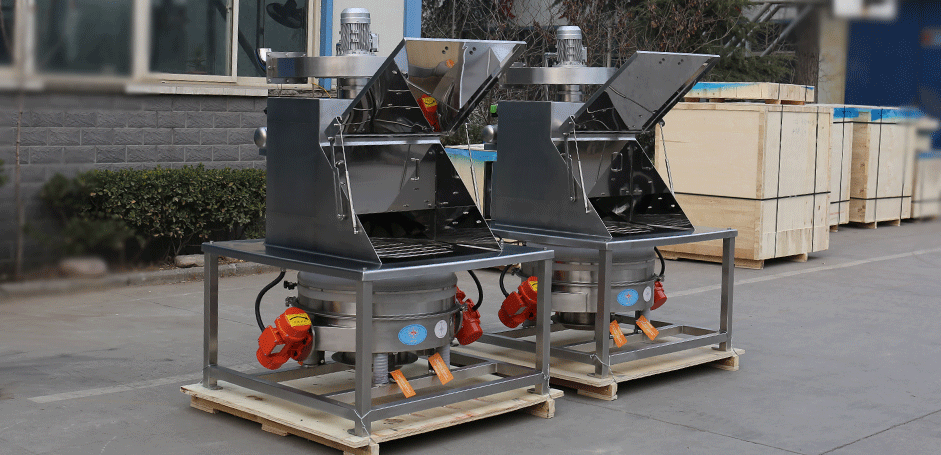

Unit integration, diverse configuration

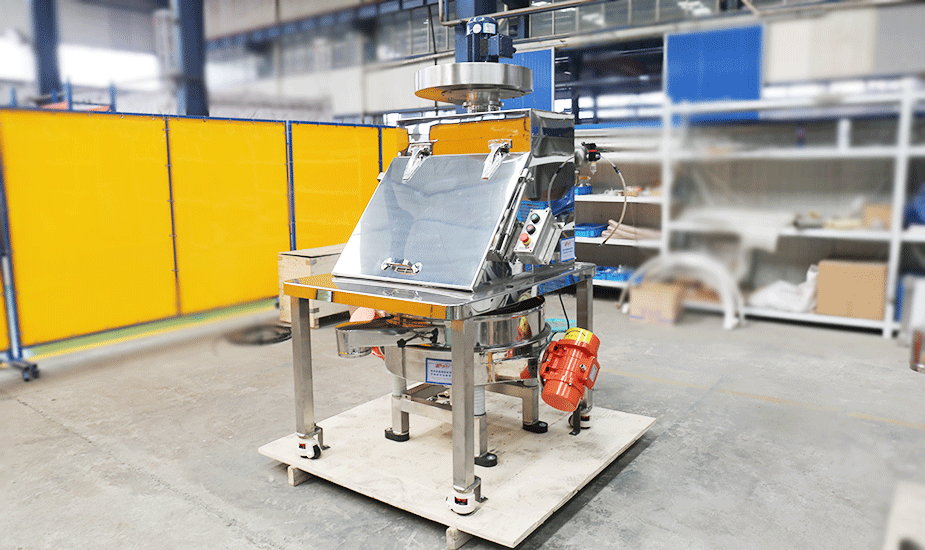

Model number:GF-800 to 1000

yield:15-500 t/h (output varies according to material characteristics)

Use:It is suitable for unpacking, placing, screening and discharging small and medium-sized bag materials in food, pharmaceutical, chemical and metallurgical industries, especially for manual feeding and

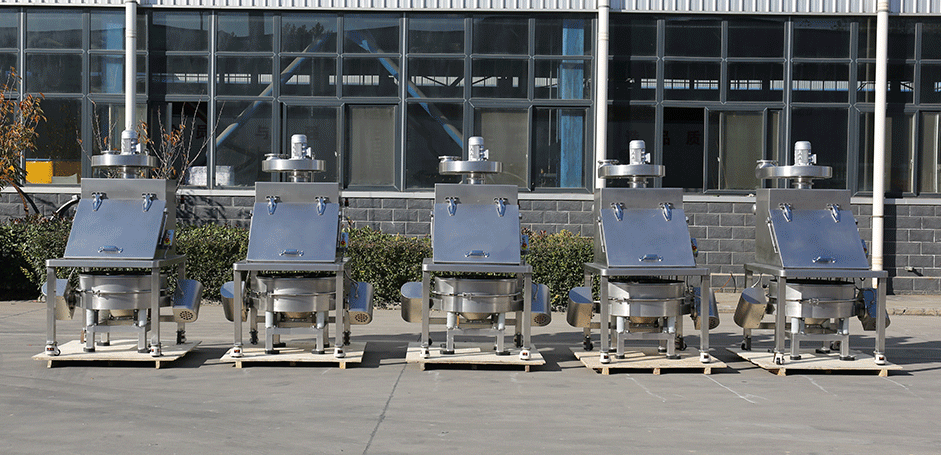

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

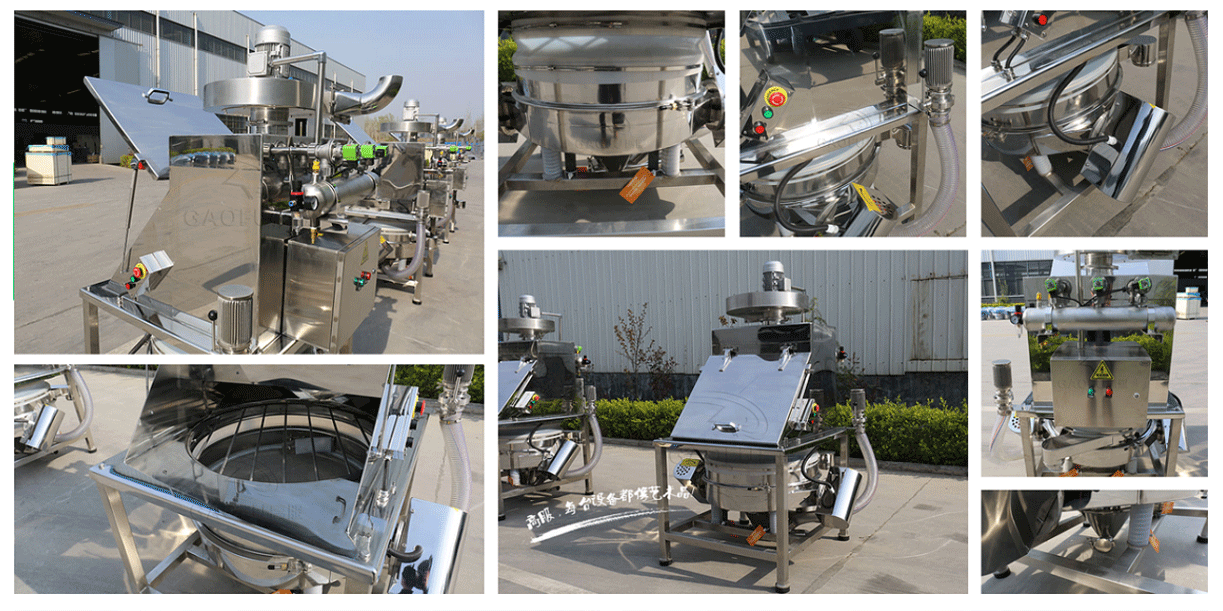

When the small bag material needs to be unbagged and poured into the next process, it only needs to be manually unpacked and put into the system, and the material dust generated during feeding is collected by the dust collecting fan. Material through the vibrating screen (screen) can block large materials and foreign bodies, so as to ensure that the required finished products (qualified materials) into the next process.

Suitable for all kinds of powder materials.

1. The dust-free screening feeding station is divided into two main parts, the upper part is dust collection, and the lower part is raw material screening or raw material transportation.

2. The upper part collects the dust to the high-density filter through the negative pressure fan, and after a period of time, the filter is backblown through the pulse device, and the dust falls into the lower straight screen for screening. The backblowing principle realizes the reuse of materials and ensures that the raw materials are not lost.

3. Lower screening equipment: It can be matched with in-line screen, rotary vibrating screen, ultrasonic vibrating screen, screw conveyor and positive pressure or vacuum conveying system.

4. The selection criteria are determined according to the customer's suitability for material screening and material receiving.

| Model number | Screening area | Power (kW) | Speed (r·p·m) | Live load | Dead load | Exciting force(kN) | Flow rate | Wind pressure |

| GF-800 | 0.42 | 2×0.18 | 1460 | 800N | 1500N | 2.5×2 | 1550-997 | 1217-1641 |

| GF-1000 | 0.64 | 2×0.25 | 1460 | 500N | 2500N | 5×2 | 1550-997 | 1217-1641 |

● Easy to clean, hygienic standard design.

● The feeding platform is in the negative pressure state, no dust leakage, no dust and environmental protection, no loss of materials during the feeding process, to protect the clean environment.

● Feeding process operation safety, reduce labor intensity, protect personnel safety production.

● Can be connected with positive pressure/negative pressure conveying to feed the production line.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!