首页>>product>>Vibrating conveyor / Bucket elevator

Unit integration, diverse configuration

Model number:No fixed model, customized according to demand

yield:15-500 t/h (output varies according to material characteristics)

Use:Food industry, pharmaceutical industry, chemical industry, other industries, etc

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

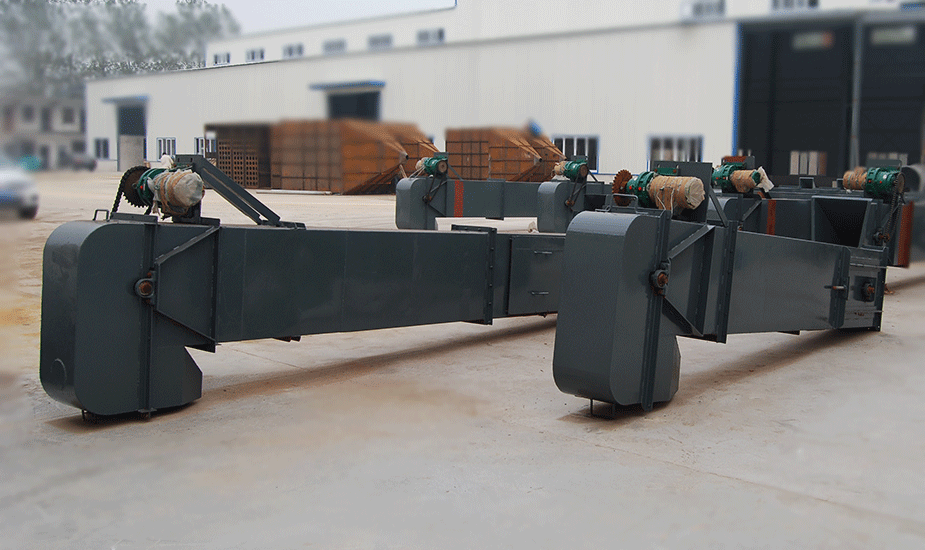

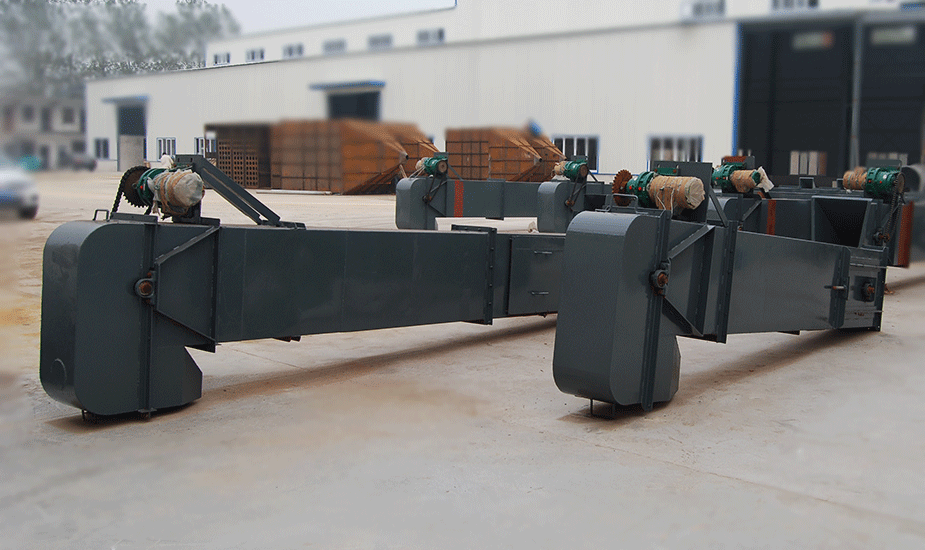

Bucket elevator is suitable for lifting from low to high, the supply material is put into the hopper through the shaking table, and the machine automatically and continuously runs upward. According to the amount of transmission can adjust the transmission speed, and choose the lifting height as needed, the hopper is designed and manufactured by itself, PP hopper makes the type of bucket elevator more widely used, all sizes are designed and manufactured according to actual needs, for supporting vertical packaging machine, computer metering machine design, suitable for food, medicine, chemical industry products, screws, nuts and other products to lift loading. The automatic stop and start of the machine can be controlled by the signal recognition of the packaging machine.

Rubber powder, magnetic materials, rubber additives, calcium powder (light calcium, heavy calcium), zinc powder, active calcium, hawthorn powder, iron oxide black, iron oxide red, Chinese medicine powder, quartz powder, etc

No fixed model, customized according to demand

● Using a series of hopper uniformly fixed on the traction member, vertical lifting material continuous conveying machinery, divided into ring chain, plate chain and belt three kinds.

● According to the transmission speed can adjust the transmission amount, and choose the lifting height as needed, the hopper is designed and manufactured by our company, and a variety of materials such as wear-resistant and corrosion-resistant can be selected according to the field work.

● Bucket elevator adopts inflow feeding, induced unloading, large-capacity hopper intensive arrangement, so that there is rarely extrusion and collision between raw materials, reducing raw materials scattered.

● Fully closed shell structure design, no dust publicity.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!