首页>>product>>vibrating screen / Bar screen

Unit integration, diverse configuration

Model number:Customize according to demand

yield:15-500 t/h (output varies according to material characteristics)

Use:Raw coal, coke, graphite pellet, petroleum coke, bottom slag, andesite, construction waste, building stone, metal ore, iron ore, limestone, fluorite, cooling blast furnace slag, etc.

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

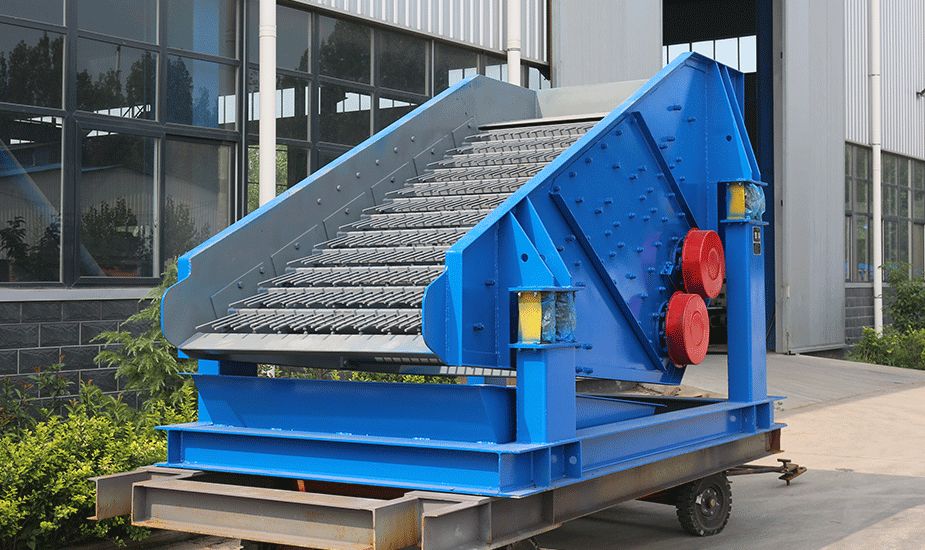

BTS bar screen is mainly used in metallurgy (iron ore, limestone, fluorite, cooling blast furnace slag, coke and other raw materials), coke, coal, coal washing, chemical industry, building materials and hydropower engineering, abrasive waste treatment, quarry and other industries of material washing, screening, grading and other industries. BTS bar vibrating screen A variety of formats and sieve size of the new structure mode sieve plate, especially for use in strong impact, high hardness, high wear resistance requirements. BTS bar vibrating screen in iron ore fine crushing screening, raw coal classification, gold, building materials and hydropower, nuclear power engineering sand screening plate.

BTS bar vibrating screen product adopts blind plate plus bar feeding surface, bar vibrating screen is suitable for uniform feeding of large material before crusher, bar vibrating screen is especially suitable for black or non-ferrous metal ore, building stone coarse or medium crushing before feeding; The bar type vibrating screen bar gap is adjustable, can separate the soil and fine crushed materials at the same time of feeding, play the crusher function behind; BTS bar vibrating screen has the characteristics of simple structure, easy maintenance, high strength, impact resistance, wear resistance, low noise and so on.

BTS bar vibrating screen is used for uniform feeding and separation of bulk materials before crusher, bar vibrating screen is especially suitable for hydropower industry, building stone and black or non-ferrous metals, ores before rough breaking feed and preliminary screening; The rod type vibrating screen vibration feeder uses vibration motor as excitation source, which is simple in structure and convenient in maintenance. Large output, long life, durable.

When BTS bar screen is working, the exciting force generated by the exciter is transmitted to the screen surface of the screen box through the screen box. Because the exciting force generated by the exciter is the longitudinal force, the screen box is forced to drive the screen surface to the longitudinal front and back displacement. Under certain conditions, the material on the screen surface is thrown forward due to the action of excited vibration force, and the material that is less than the screen hole falls through the screen and falls to the lower level. The motion track of the BTS bar vibrating screen material on the screen surface is parabolic motion, and the bar sieve completes the material screening operation due to such cyclic material movement.

No, customized as required

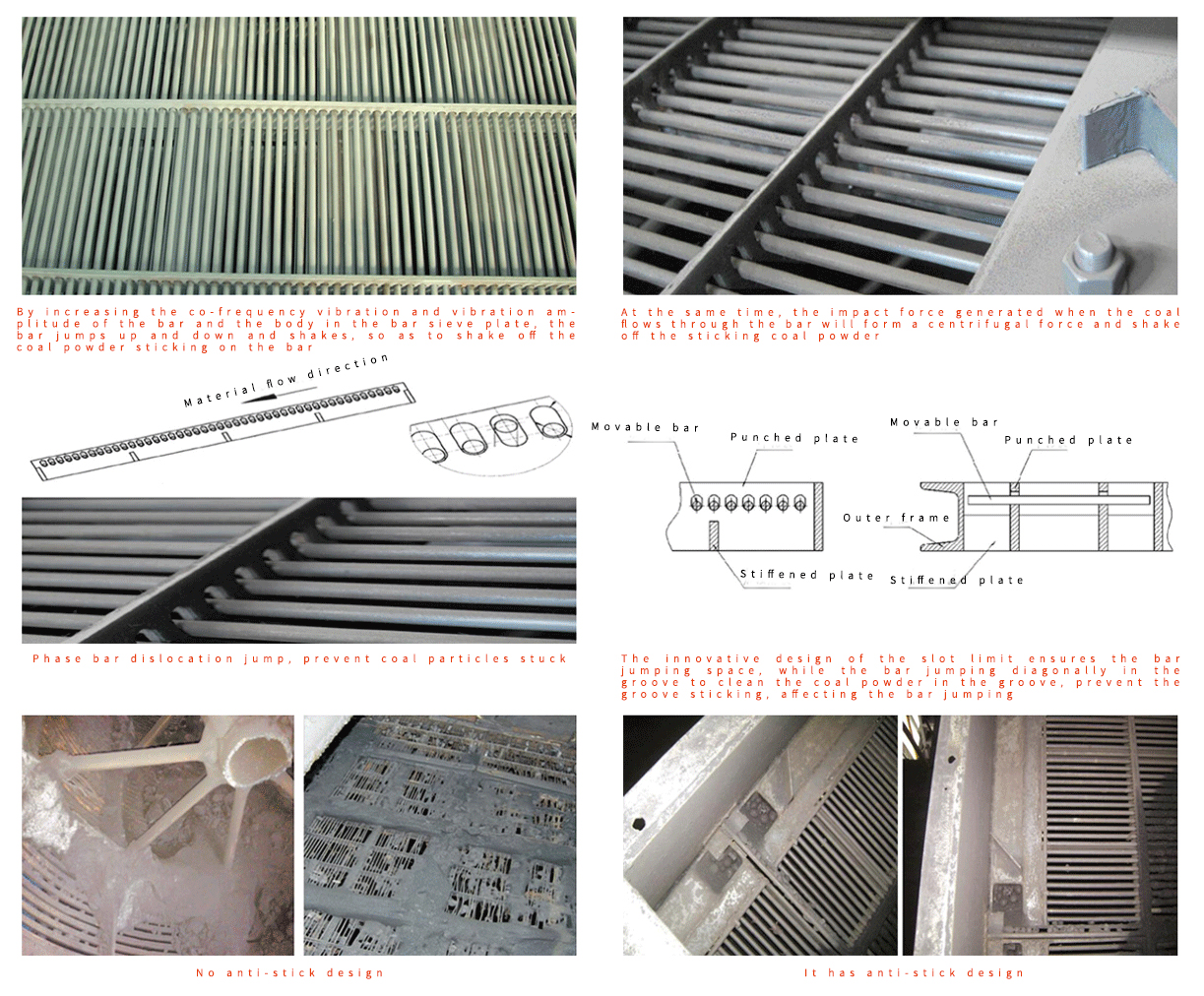

Quadruple anti-stick design

Self-cleaning adhesive materials

The exciting force is large

New type vibrator, high energy saving, large exciting force

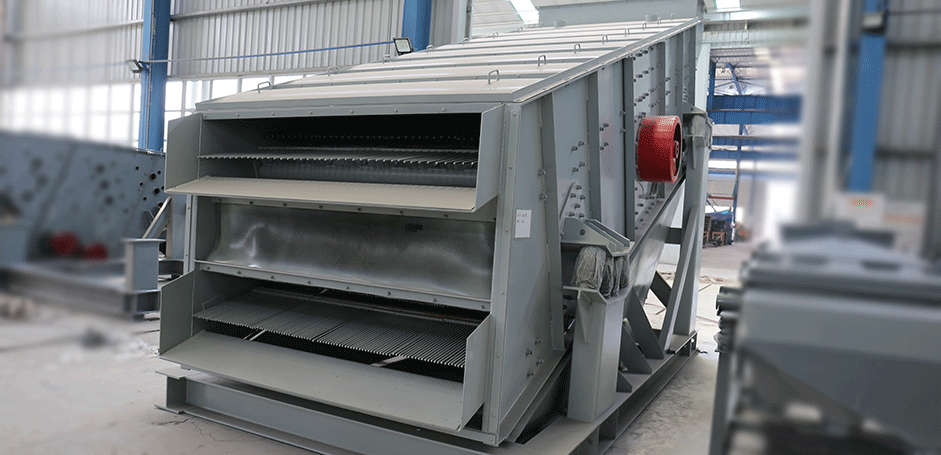

Two forms of structure

Open type, closed type two forms

Widely used

Grading treatment of bulk and medium and small granular materials

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!