首页>>product>>Industrial Vibrating Screen / Air flow screen

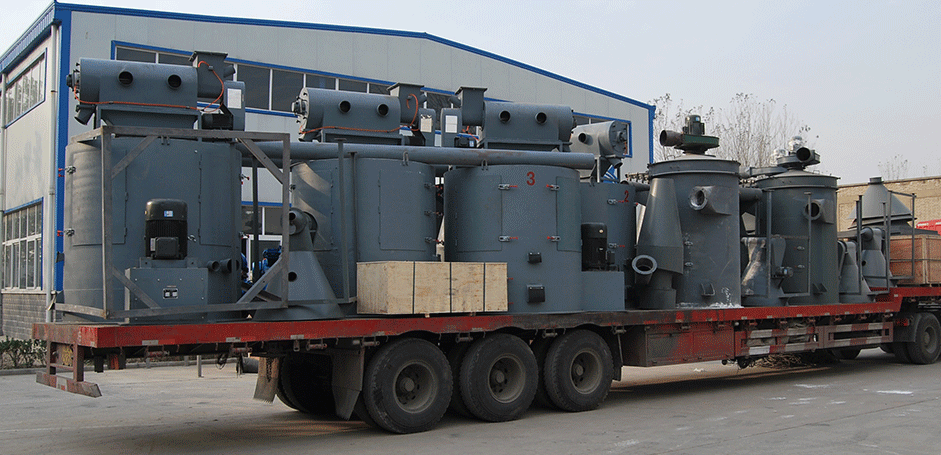

Unit integration, diverse configuration

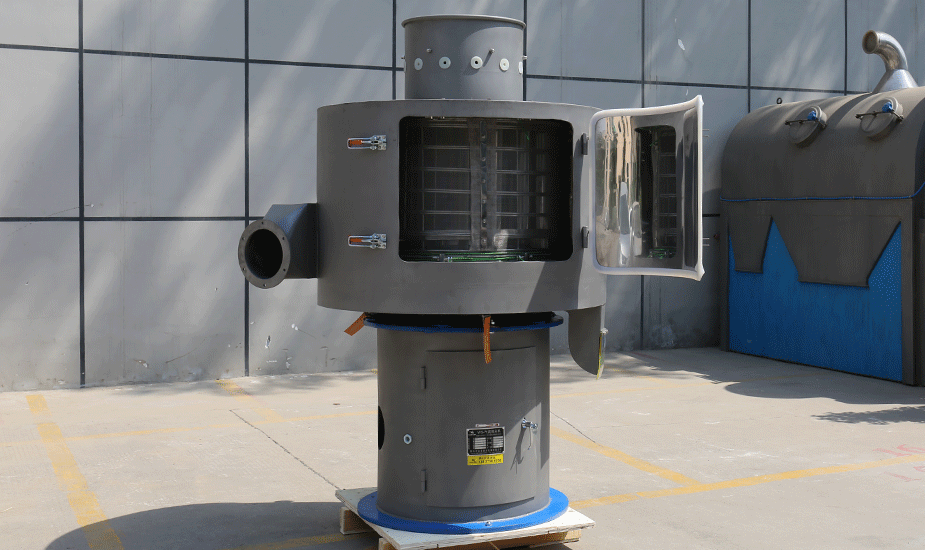

Model number:WS-600 to 1800

yield:15-500 t/h/ output varies according to material characteristics

Use:Zinc powder, graphite powder, tree fat powder, Chinese medicine powder, paint, fly ash, wood powder, rubber additives, talc powder and other materials

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

WS air flow screen referred to as cyclone screen using air as the carrier, kinetic energy work principle. The raw material mixture enters the body from the air inlet, and is reinforced by the intelligent turbine, so that the dispersed monomer of the raw material passes orderly through the composite screen, and enters the next process in the downwind direction. The unqualified foreign matter is intercepted and discharged through the automatic slag discharge port. This completes the selection process for networked jobs.

It is connected in series in the wind path of raw material production, and the raw material mixture enters the body from the inlet of the air screen, and is reinforced by the intelligent turbine, so that the raw material is dispersed into a single unit and passes through the composite screen in an orderly manner, and enters the next process in the downwind direction. The unqualified foreign matter is intercepted and automatically discharged through the automatic slag discharge port. Thus, the selection process of networked jobs is completed. The use of air atomization to disperse raw materials into monomer, to overcome the material sticky, agglomeration, electrostatic adsorption, light floating, caking and other difficult screening characteristics, to achieve the traditional screening machinery can not be effective screening purpose. It is a comprehensive use of centrifugal force, wind, gas eddy current, mechanical kinetic energy, gravitational potential energy and vibration force and other intelligent screening equipment.

| Model number | Air flow (m³/h) | Screen size (mesh) | Feed size (mesh) | Screen power (kW) | Spindle speed (r.p.m) | Screen outside diameter (mm) | Full height (mm) |

| WS-600 | 240-1100 | 80-600mesh | 40mesh≤ | 3 | 420 | Φ606 | 380 |

| WS-1000 | 200-2500 | 5.5/7.5 | 960 | Φ1006 | 730 | ||

| WS-1600 | 500-2600 | 11/15 | 970 | Φ1500 | 2335 | ||

| WS-1800 | 720-7200 | 22 | 650 | Φ1800 | 1802 |

· High efficiency

The screening efficiency is higher than 95

· High yield

5-10 times or more of the shaker

· Wide range of adaptability

80-530 mesh all kinds of powder materials can be screened

· Fineness is accurate

No mixing phenomenon

· Long service life

Vertical screen installation, no load bearing

· No dust pollution

The screening procedure is carried out in the negative pressure semi-cycle state

· Can be used together

It can be used with all kinds of mills and wind types connected to the grid

· Save costs

Low noise, low energy consumption, continuous operation, reduce maintenance

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!