首页>>product>>Industrial Vibrating Screen / Inline Screen

Unit integration, diverse configuration

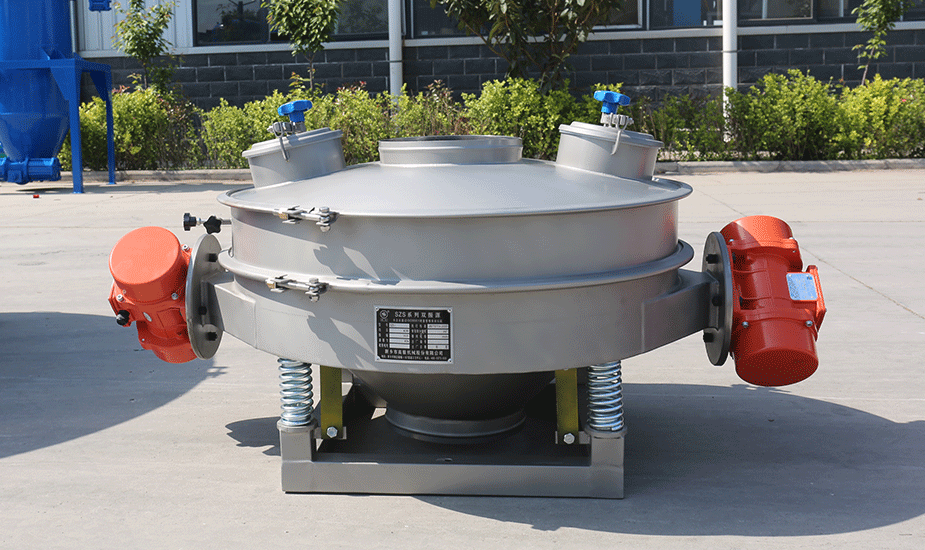

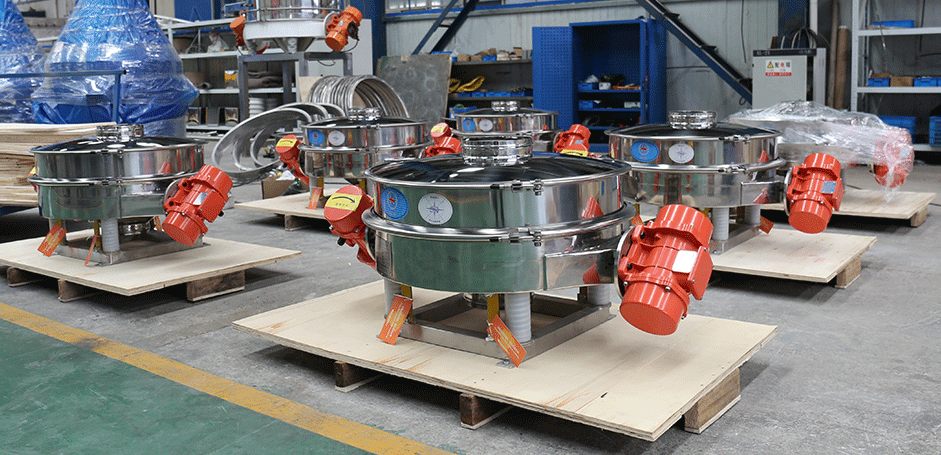

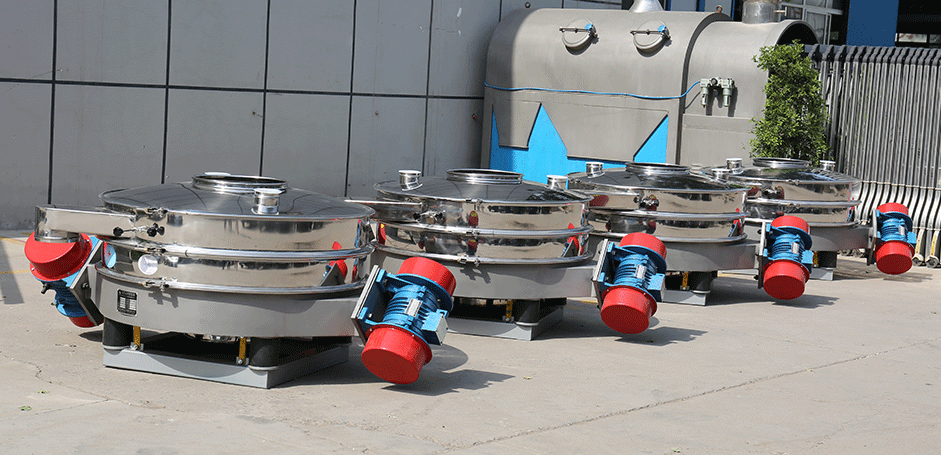

Model number:SZS-600 to 1500

yield:15-500 t/h (output varies according to material characteristics)

Use:Flour, starch, fluorescent powder, feldspar powder, kaolin, silica black soil, fly ash, glass beads, environmental protection, plastic, plastic, rubber, coating, alloy powder, gold powder, silver powd

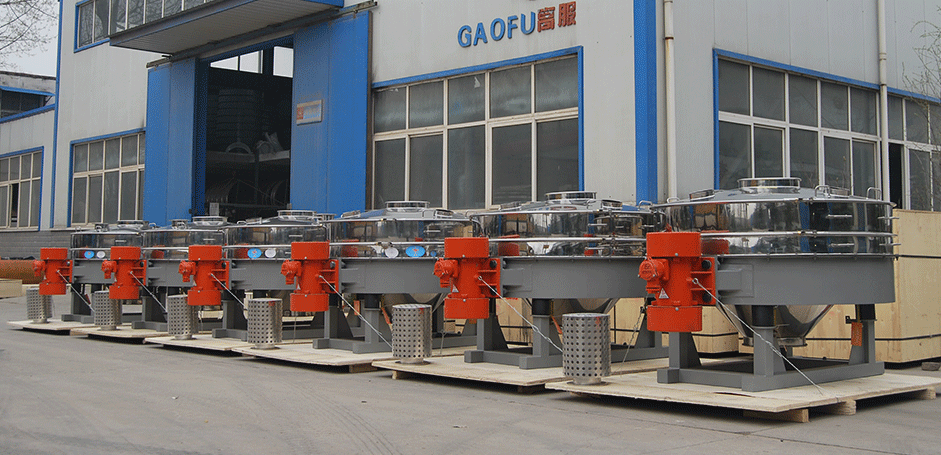

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

Inline screen is also called vibrating screen machine, vibrating inline screen. It has different names for different vibration sources, such as single-vibration source inline screen and double-vibration source inline screen. Gaofu inline screen meets the standards for use in the food and pharmaceutical industries. It is suitable for quickly removing oversized materials from powders and granules, that is, for peeling and inspection screening. It is a screening device suitable for raw material and finished product inspection before packaging. It loads and unloads materials vertically and can be connected in series in the production line.

The inline screen uses a high-frequency vibration motor as the excitation source. After the material enters the system, it is subjected to the force of the vibration source to make a three-dimensional rotation motion on the screen surface. The flour and lumps are fully dispersed and quickly pass through the screen directly into the lower flour bin. Impurities and foreign matter are separated and discharged to the slag discharge port, playing the role of a "quality inspector" on the production line.

| Product Model | power (kW) | Motor speed (r/min) | Screen diameter (mm) | Dimensions (mm) |

| SZS-600 | 2×0.18 | 1460 | Φ560 | 1150×600×550 |

| SZS-800 | 2×0.18 | 1460 | Φ760 | 1360×800×600 |

| SZS-1000 | 2×0.25 | 1460 | Φ930 | 1600×1000×700 |

| SZS-1200 | 2×0.55 | 1460 | Φ1160 | 2000×1200×900 |

| SZS-1500 | 2×0.75 | 1460 | Φ1430 | 2350×1500×1000 |

The flat design of the in-line screen equipment is convenient for manual operation, small in size and easy to move

The in-line screen can be connected in series to the production line system, with low energy consumption and high efficiency

The inside and outside are easy to clean, there is no sanitary dead corner, and it meets the standards for use in the food and pharmaceutical industries

The in-line screen is automated and can be produced continuously for 24 hours

Ultra-quiet bass design, normally 70 decibels

The in-line screen is strictly sealed, liquid does not leak, and dust does not fly

The in-line screen structure and mesh frame design improve the durability of the screen, the screen is quick to change, and it is easy to disassemble and assemble, so that the screen change problem can be completed within 5 minutes

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!