首页>>product>>vibrating screen / Dewatering screen

Unit integration, diverse configuration

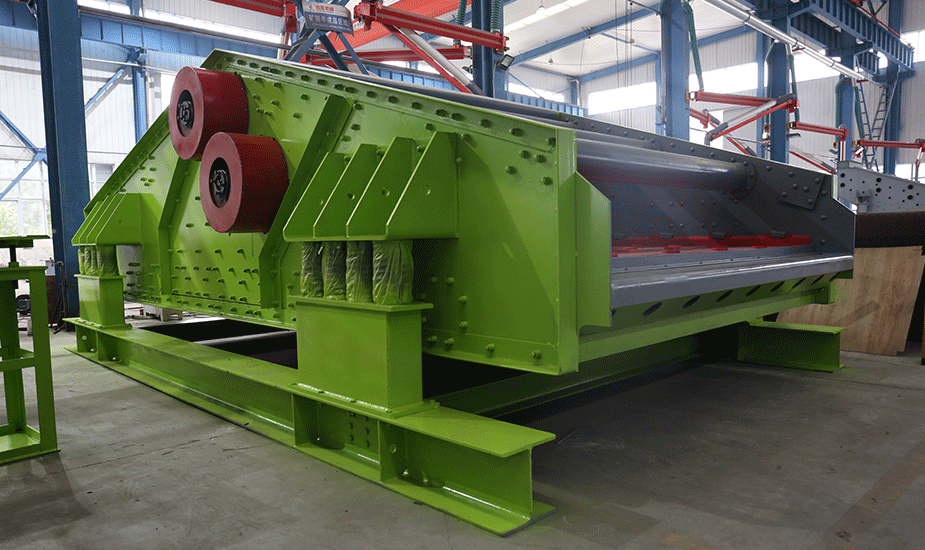

Model number:GFVD1036 to 2538 (Special models need to be customized)

yield:15-500 t/h (output varies according to material characteristics)

Use:Dewatering, deintermediation and desliming of coal slime in coal industry; In the chemical industry, fine grain dry and wet screening, dehydration and deintermediation; Environmental protection indust

Because you need it, and we specialize. Welcome to visit the factory!

Consult ustelephone:0373-5701114

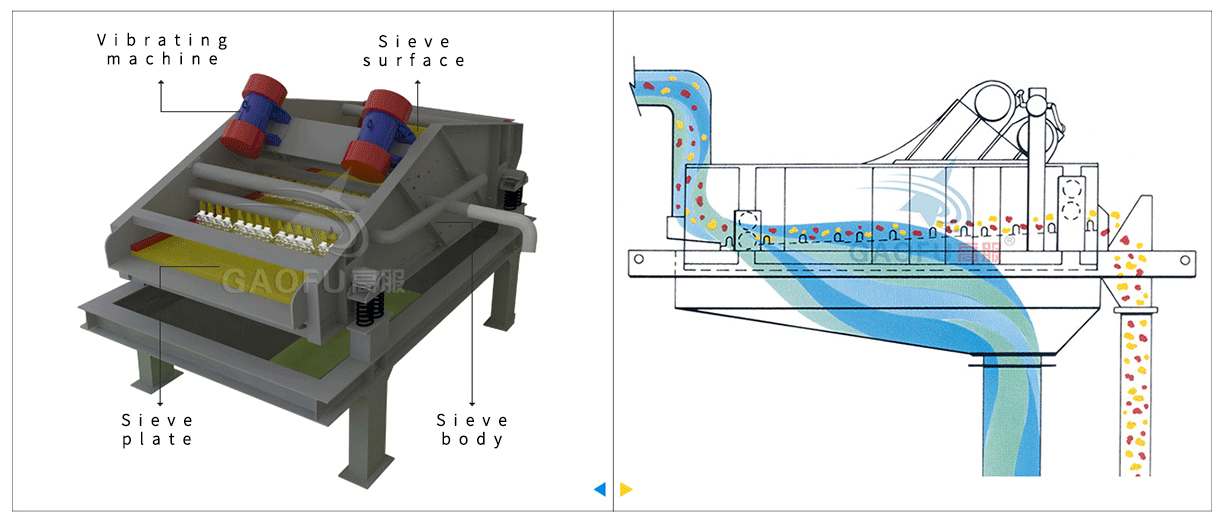

Dewatering screen, also known as high-frequency dewatering screen, changes the water tension on the surface of the pulp through the exciting vibration force, the pulp water becomes the material under the screen through the screen, and the fine material is blocked by the screen to form a filter layer affected by the vibration force to move forward and discharge. The dewatering screen is mainly used for tailings dewatering in the mineral processing industry, coal sludge dewatering in the coal preparation plant, washed-quartz sand dewatering and ceramic mud dewatering, as well as for the dry and wet classification, dewatering, desliming and desliming of medium and fine granular materials in the industrial sectors of power, sugar, salt and so on.

Application materials: iron tailings, gold tailings, copper tailings, vanadium tailings, lead zinc tailings, graphite tailings, quartz sand, zirconium sand, glass sand, construction sand, casting sand, building materials sand, potassium feldspar dehydration, urban sewage, industrial sewage, river sludge solid-liquid separation, sewage treatment plant filtration.

Dewatering vibrating screen adopts double electrode self-synchronization technology, universal eccentric block, adjustable amplitude vibrator. It is mainly composed of screen box, vibration exciter, support system and motor.

The two unrelated vibrators are respectively driven by the belt coupling shaft for synchronous reverse operation, and the centrifugal force generated by the two sets of eccentric mass is superimposed along the vibration direction, and the reverse centrifugal is offset, thus forming a single excited vibration along the vibration direction, so that the screen box moves in a reciprocating straight line.

| Model number | Screen bevel Angle(°) | Commonly used sieve size(mm) | Input amount(t/h) | Energy consumption of power source(kW) | Reference gross weight(t) |

| GFVD1036 | -5~-3 | 0.3~0.6 | 10~35 | 2 ×1.1 | 3.8 |

| GFVD1236 | -5~-3 | 18~65 | 2 ×2.4 | 4.5 | |

| GFVD1536 | -5~-3 | 30~90 | 2 ×3.1 | 5.7 | |

| GFVD1838 | -5~-3 | 40~120 | 2 ×7.5 | 6.6 | |

| GFVD2138 | -3~0 | 60~150 | 2 ×7.5 | 8.2 | |

| GFVD2538 | -3~0 | 80~200 | 2 ×11 | 11 |

● Relatively small size, large processing capacity per unit area, easy to arrange the system process.

● High wear-resistant screen plate long service life, modular assembly design, easy to replace.

● V-shaped sieve surface design, -5゜ sieve surface climbing dehydration, dry discharge tailings low water content, high efficiency.

● Specially designed frequency, amplitude, low power source, suitable for a variety of dehydration needs 24 hours continuous dry discharge operation.

● The type steel components are riveted and welded together to form a frame body with no internal stress, high strength, light weight and durability.

Note: Ranked in no particular order, part.

Senior service building

Senior service building High service research building

High service research building

Senior staff photo

Senior staff photo

Aerial view of the plant area

Aerial view of the plant area

With the continuous innovation of technology and technology, Gao service for our customers!